Six Big Losses #3 -The Slow Cycle

Six Big Losses in OEE #3 The Slow Cycle

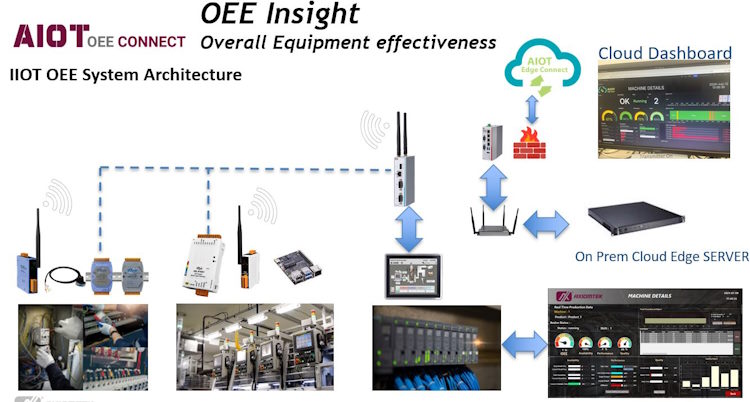

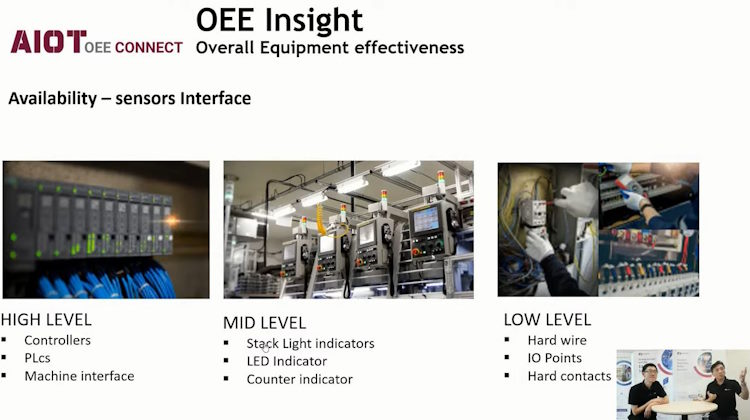

SLOW --> BIG !😉 Why? When it is concerning the heartbeat of the production, so it is BIG!🧨The 6 Big losses #3 -The Slow Cycle.In any manufacturing environment, cycle time is more than just a metric—it's the heartbeat of the production system. Each completed cycle represents a unit of output, and when those beats slow down, so does productivity.That’s why monitoring cycle time is so critical. It tells you, in real time, whether your production line is healthy and performing at its best—or if there are hidden inefficiencies slowing things down.When you walk through a modern production floor, you’ll often see digital boards displaying Target Output vs. Actual Output. This real-time feedback loop creates operator awareness, helping them stay aligned with expected production goals. It also acts as a subtle productivity cue, letting teams know if the "heartbeat" of the process is slowing.This slowdown—known as a slow cycle—can be caused by...