AIoT – Operational Technology

Revisiting OT ( The operational Technology )

While talking to people is always enjoyable, making machines that can communicate with each other is even more fascinating!The shop floor used to be synonymous with earning extra through "OT" 😉 —overtime. But these days, "OT" has taken on a whole new dimension: Operational Technology. Our focus has shifted from extra hours to extra intelligence—connecting machines, sensors, and systems in smarter ways.When building efficient and reliable IIoT edge devices under resource constraints, the choice of operating system plays a vital role. And extracting data from Japanese PLCs brings its own set of challenges, thanks to their tightly guarded, proprietary communication methods.Revisiting OT—this time as the foundation for AI—marks the beginning of an exciting new chapter in our industrial transformation journey.

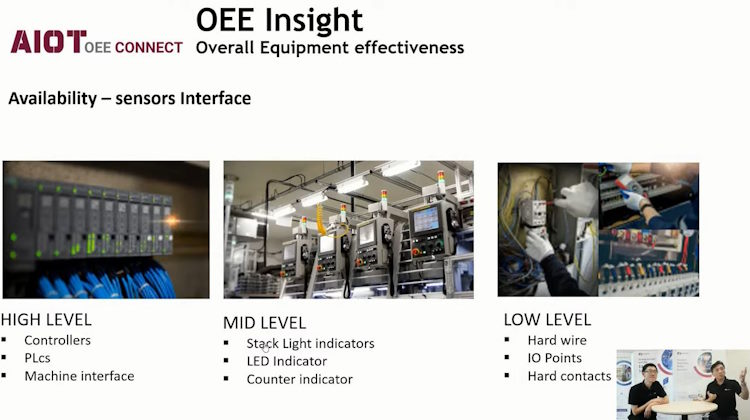

The foundation of any AI initiative in manufacturing begins with effective shop floor data collection. One common challenge is integrating data from existing equipment, particularly when it involves legacy systems or machines automated with proprietary...