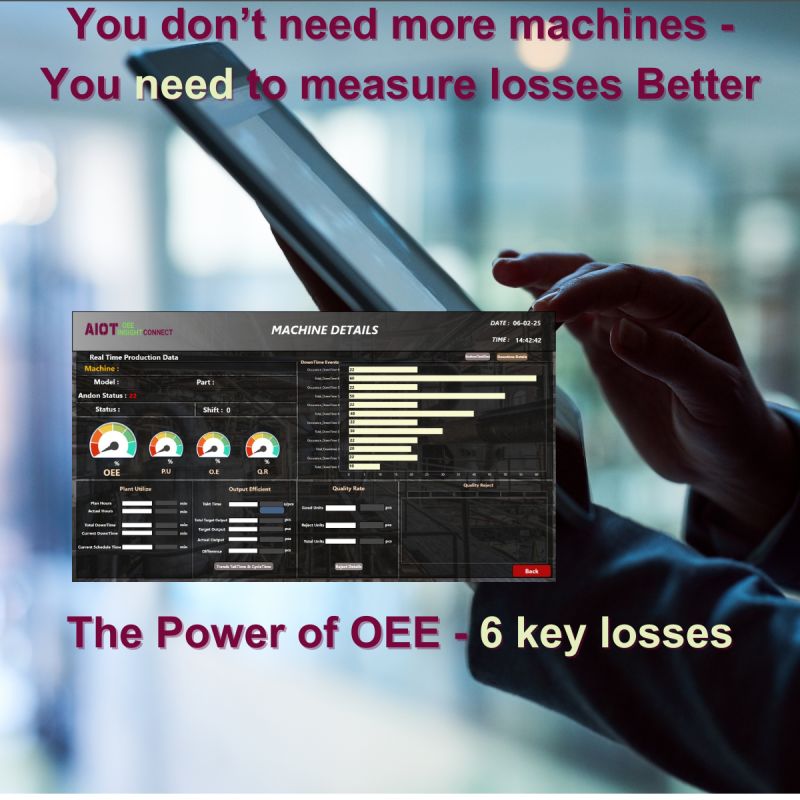

“You Don’t Need More Machines—You Need to Measure Losses Better”

When customer orders keep piling in and production can’t keep up, the first instinct is often:

“We need another machine and it cost 100K ” But do you really need that?

Let’s look at this scenario:

You have 10 machines, each producing 100 units/day. You’re running at 60% OEE.

New demand = 1,100 units/day (but you’re only producing 1,000)

So you’re 100 units short—and considering spending $100,000 on a new line

👉 But what if the capacity you need is already there—hidden inside inefficiencies?

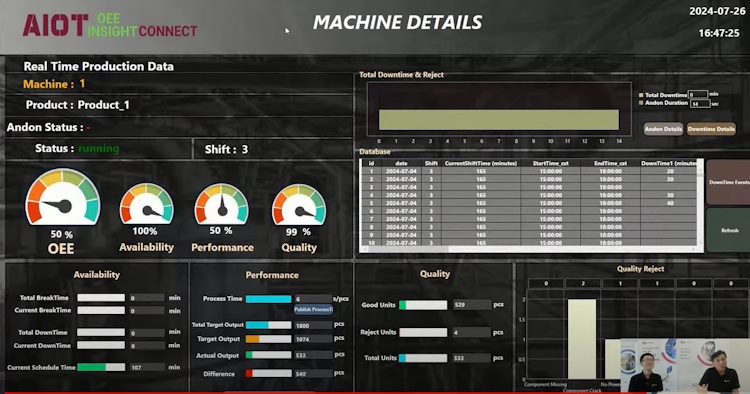

By understanding and addressing the 6 Big Losses of OEE—(like minor stops, reduced speed, and quality issues)—you improve your OEE from 60% to 70%.

That 10% increase now means each machine produces 110 units/day.

End Result:

10 machines × 110 units = 1,100 units/day

No new machine needed

$100K investment saved

And long-term gains through sustained efficiency

The Takeaway ( by distilling your efficiency with the tracking of 6 key losses) :

Tracking the 6 Key OEE Losses isn’t just about monitoring performance—

it’s about unlocking trapped capacity, avoiding unnecessary investments, and turning existing assets into high-performing systems.

find out more about the AIoT OEE insight Connect.