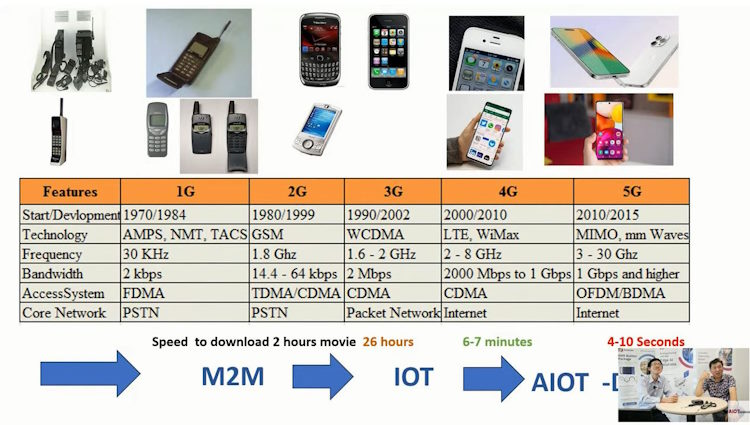

Welcome everyone to our “Sembang AIoT” live session, where today, on the 10th of May 2024, we delve into the dynamic realm of 5G infrastructure within the sphere of Smart Manufacturing. As the world continues its rapid march towards digitization, the integration of Artificial Intelligence and the Internet of Things (AIoT) into manufacturing processes has become not just a trend but a necessity for staying competitive in today’s market. With 5G technology revolutionizing connectivity, the possibilities for enhancing efficiency, productivity, and agility in manufacturing are boundless. In this session, we will explore the transformative potential of 5G infrastructure, its applications, challenges, and the promising future it holds for the manufacturing landscape. So, let’s embark on this journey together and uncover the intricacies of 5G in Smart Manufacturing!

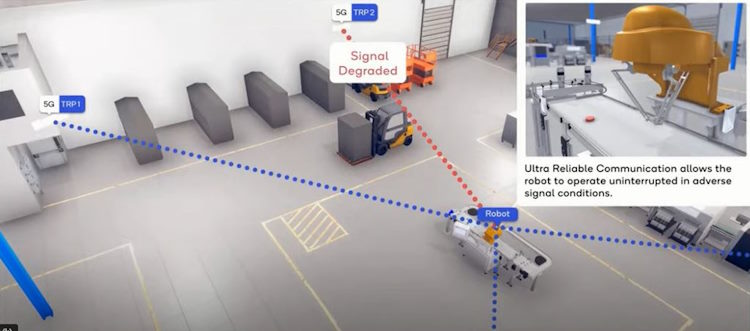

The picture above show how 5G is able to have its redundant path in avoiding signal breakage due to the obstable.

While 5G technology is not an absolute necessity for Smart Manufacturing, its integration can significantly enhance the possibilities within this domain. Smart Manufacturing primarily revolves around the efficient utilization of data, automation, and connectivity to optimize processes and drive innovation. Here’s how 5G can play a pivotal role in enhancing the possibilities of Smart Manufacturing:

Ultra-Reliable Low-Latency Communication (URLLC): One of the key features of 5G is its ultra-low latency, which enables near-real-time communication between devices and systems. In Smart Manufacturing, where split-second decision-making is crucial, URLLC ensures that critical data is transmitted instantly, allowing for rapid responses to dynamic production environments.

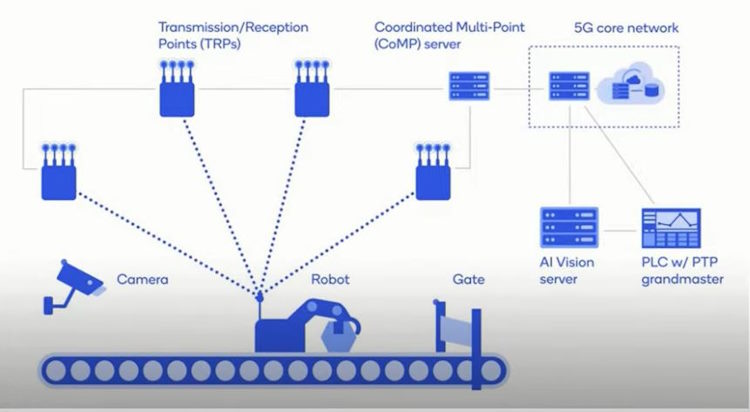

Massive Machine-Type Communication (mMTC): 5G’s ability to support a massive number of connected devices per square kilometer is instrumental in scaling up the Internet of Things (IoT) infrastructure in manufacturing facilities. This enables seamless connectivity between a myriad of sensors, machines, and devices, facilitating comprehensive data collection and analysis for informed decision-making.

High Bandwidth and Throughput: With its significantly higher bandwidth and throughput compared to previous generations of mobile networks, 5G enables the transfer of large volumes of data at lightning speeds. This capability is invaluable in Smart Manufacturing scenarios where high-definition video streams, augmented reality (AR), virtual reality (VR), and other data-intensive applications are utilized for tasks such as remote monitoring, predictive maintenance, and quality control.

Network Slicing: 5G introduces the concept of network slicing, allowing for the creation of virtualized, isolated network segments tailored to specific use cases. In Smart Manufacturing, this enables the allocation of network resources based on the requirements of different production processes, ensuring optimal performance, security, and reliability.

Enhanced Mobility Support: In manufacturing environments where mobility is essential, such as in the case of autonomous mobile robots (AMRs) or wearable devices worn by workers, 5G’s seamless handover capabilities and support for high-speed mobility ensure uninterrupted connectivity and communication.

While 5G is not indispensable for Smart Manufacturing, its adoption can unlock new levels of efficiency, flexibility, and innovation within manufacturing processes. By leveraging the unique capabilities of 5G, manufacturers can create agile, interconnected ecosystems that empower them to adapt to evolving market demands, optimize resource utilization, and drive sustainable growth.

Ultra-low latency offered by 5G technology revolutionizes robotic applications and AI vision in Smart Manufacturing by enabling instantaneous communication and decision-making. In robotic applications, where precision and agility are paramount, ultra-low latency ensures that commands from central control systems reach robots in real-time, allowing for swift adjustments to changing production conditions. This instantaneous responsiveness enhances the efficiency of tasks such as pick-and-place operations, assembly, and material handling, leading to optimized throughput and reduced downtime. Similarly, in AI vision applications, ultra-low latency facilitates rapid data transmission between cameras, edge computing devices, and AI algorithms, enabling real-time analysis of visual data streams. This capability enables AI vision systems to detect defects, anomalies, or safety hazards with unparalleled speed and accuracy, empowering manufacturers to implement proactive quality control measures and ensure compliance with stringent safety standards. Overall, ultra-low latency provided by 5G technology unlocks new possibilities for robotics and AI vision applications in Smart Manufacturing, paving the way for enhanced productivity, quality, and operational efficiency.

https://youtube.com/live/WAjXbrFXHM0