Energizing Smart Manufacturing with AI Data analytic

A live session in April presented by AIoTmission AIoT Team began with a discussion on how to energize smart Manufacturing with AI Data Analytics.

Data analytics plays a crucial role in smart manufacturing for several reasons:

Optimizing Processes: Data analytics allows manufacturers to collect, process, and analyze large amounts of data from various sources within the manufacturing process. This enables them to identify inefficiencies, bottlenecks, and areas for improvement, leading to optimized processes and increased productivity.

Predictive Maintenance: By analyzing data from sensors embedded in machinery and equipment, manufacturers can predict when maintenance is needed before a breakdown occurs. This proactive approach reduces downtime, lowers maintenance costs, and extends the lifespan of machinery.

Quality Control: Analyzing data from production processes can help identify defects or anomalies in real-time, allowing manufacturers to take corrective action immediately. This ensures that products meet quality standards and reduces the likelihood of defects reaching customers.

Supply Chain Optimization: Data analytics can provide insights into supply chain dynamics, such as demand forecasting, inventory management, and supplier performance. By optimizing the supply chain based on data-driven insights, manufacturers can reduce costs, improve efficiency, and enhance overall competitiveness.

Energy Efficiency: Analyzing data related to energy consumption can help identify opportunities for reducing energy usage and optimizing energy efficiency in manufacturing operations. This not only lowers operational costs but also contributes to sustainability efforts by reducing environmental impact.

Customization and Personalization: Smart manufacturing enables greater customization and personalization of products to meet individual customer needs. Data analytics can help manufacturers gather and analyze customer data to understand preferences and trends, allowing them to tailor products and services accordingly.

Continuous Improvement: By continuously analyzing data from various aspects of the manufacturing process, manufacturers can identify areas for improvement and implement iterative changes to drive continuous improvement. This data-driven approach fosters innovation and agility in adapting to changing market conditions.

Overall, data analytics is essential in smart manufacturing because it empowers manufacturers to make informed decisions, improve efficiency, enhance quality, and remain competitive in today’s dynamic business environment.

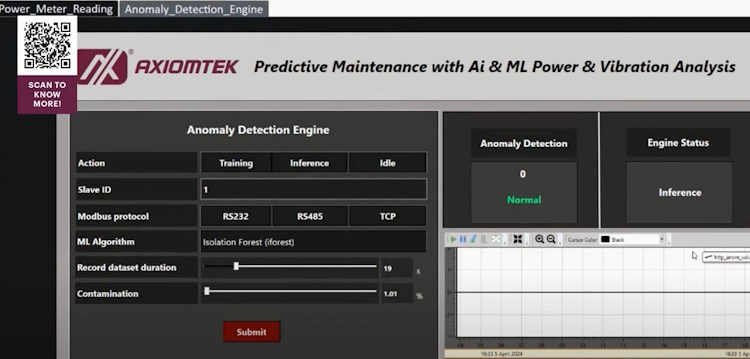

We presented a simulated case with the real live data and system that perform the Data Analytic on predictive maintenance during the session.

Vibration analysis can be one important source of detecting if the process or equipment is starting to behave abnormally and lead to complete failure later on that cause the down time in the manufacturing process. In an example of motor or pump used in the process, the abnormality of the acceleration, velocity and amplitude can be a source of early warning that some parts need to be repaired or replaced.

We used a cooler fan to generate the standard vibration data and fed that to the IIOT edge gateway or 4G IOT gateway router, in this case data are being published to the cloud. The local SCADA in this case , ADISRA SCADA software is used to manage the source of the data, training of the AI model of the data and presenting the inference result from the ML analytic result which is performed at the Cloud level. In the previous session, we mentioned about the the Fog Computing where in order to run the AI or data analytic more efficiently, the fog computer or nodes is used.

Vibrational data collected and presented by SCADA Dashboard.

SCADA Dashboard was created to allow the anomaly detection AI to operate and perform the live data analytic. You can see from the right hand side of the picture above, the green color normal state is shown when the AI detected the current data are within the range. In this case, we are talking about the the group of data detected by the AI engine and it is not the single piece of data. The session ended with the wishes to all Muslims ” Selamat Hari Raya” drive safe to the home town during this celebration.

There are several sub topic discussed in the session like the challenges faced by the manufacturing in implementing of AI and others examples of AI being used in the manufacturing sectors as well.

to watch the session in AioTmission Youtube channel :-