Step into the future with our unrivaled expertise! With over 25 years of experience in Industrial PC-based Automation and SCADA system integration, our professional services and training programs have been meticulously crafted to propel you into the world of Industry 4.0 and Digital Transformation.

Unlock the potential of smart manufacturing with our cutting-edge IoT and AI starter kit, a vital component of the IR4 program successfully deployed at the prestigious Malaysia Production Center (MPC). As an accredited HRDF Training Provider, we are committed to empowering businesses through AI and IoT applications in their digital transformation journey.

Confidence in our capabilities is built on a solid foundation of tackling intricate client challenges and delivering tangible results. Many clients have forged lasting partnerships with us, entrusting us with their goals and ambitions across multiple engagements.

Our comprehensive range of services includes consultancy and Training in Digital Transformation & Industry 4.0, SCADA and Telemetry system design, and guidance for adopting digital solutions in shop floors and manufacturing processes.

Venture into the realm of IoT and AI with our expert assistance, offering system development consultancy and IR4 readiness preparation.

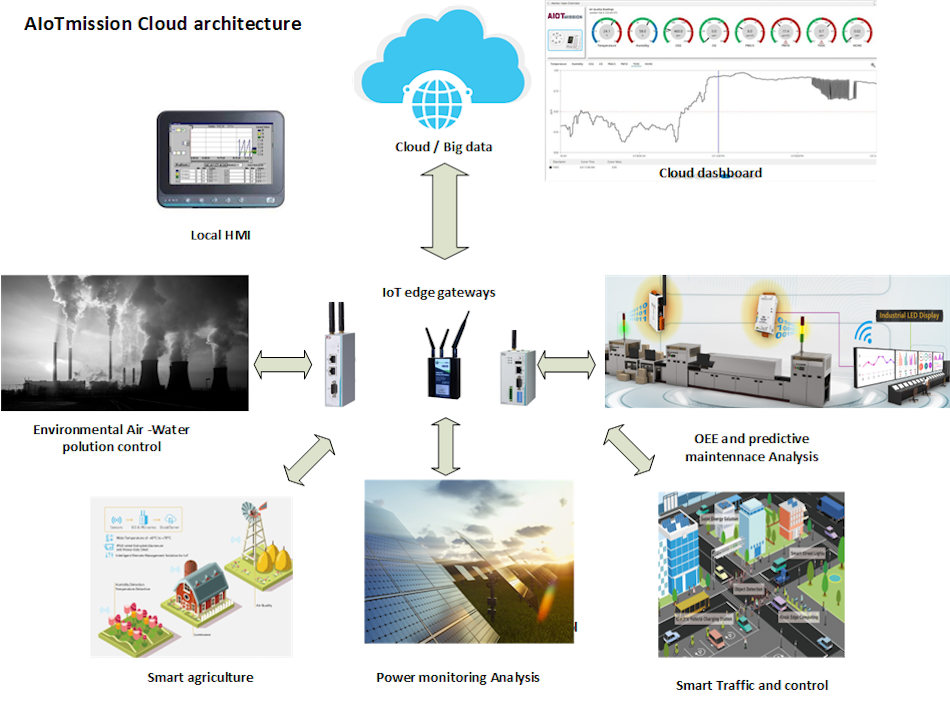

The future belongs to smart cities, smart agriculture, and smart manufacturing, and our AIoT cloud integration expertise stands ready to shape this landscape. Embrace the seamless fusion of AIoT Edge Connect devices with cloud integration, and witness the transformative power of our training programs.

Be prepared for the future, join us on the journey of Digital Transformation, and experience innovation like never before!

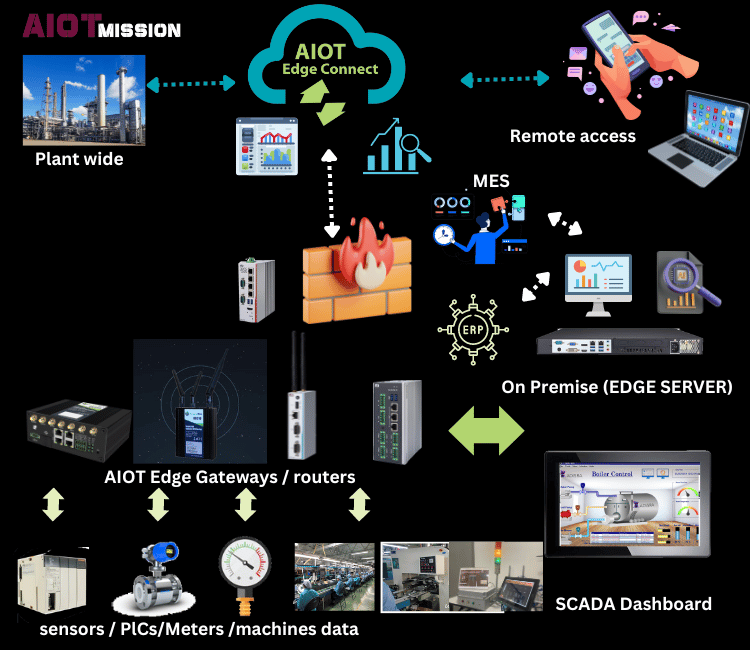

AIOT EDGE CONNECT - CLOUD Platform

AIOT EDGE CONNECT

AIoT Edge Connect Cloud Platform allow users in their own applications to publish data to the Cloud platform. The current Cloud platform is sitting on the Microsoft Azure where it serve all the connected AIoT devices.

Supported Communication protocols:-

- MQTT

- WEB API / RESTFUL API

It is currently capable of handling the followings:-

- Visualization of data on the Dashboard

- Historian or Data logging

- Alert management where alarms or any out of spec. data can be escalated as messaging via Email, Whatsapp, Telegram and SMS.

- Reporting ( optional )

AIOT Edge Connect is cloud & Cloud enabled device platform that serve in the different industry that require Digitalization with BIG Data. The platform is currently available for our client to host their data and manage it on the cloud. Find out more with the link below:-

AIOT AIS CONNECT - A Development Vision AI Suite

AIOT AIS CONNECT

AIOT AIS CONNECT is an AI Development platform featuring a high-performance Intel® Core™-based AI edge platform IPC524 with high-computing GPU/ VPU support, a high-resolution camera, and built-in Axiomtek AI suite (AIS) based on Tensorflow Framework, Intel® Edge Software Hub for Industrial and Intel® OpenVINO™. This application-ready package enables manufacturers to ease the development of vision applications within automation. The hardware platform, IPC524, is a 7-slots industrial PC system with LGA1151 socket 9th gen Intel® Core™ i7 ® processor. It comes with front-access I/O and adequate PCIe and PCI Slots. The Axiomtek AI Suite (AIS) is based on Intel® Edge Software Hub for Industrial to implement from deep-learning training to inference. It comes with web apps design and intuitive user interfaces, helping the users deploy AI without coding.

AI Suite features:

Deploy without programming: web apps design with simple and intuitive user

interfaces

● Fine tuned Intel® Edge Software Hub for Industrial: support both model optimizer and

inference engine by Intel® OpenVINO™

● End-to end deep learning: all-in-one implementation from training to inference

● Built-in dashboard components: simple dashboard components for users to easily

and quickly deploy training and inference & Light weight SCADA Engine that allow presentation of data on a Display

● Built-in communication protocol like MQTT and REsful API that allows AI data to be shared or published to the other system dashboard and cloud server.

● Axiomtek AI Edge compatible – Allow users to deploy onto any of the suitable AI Edge platforms or IPC systems to run any of the destined environments in the industry.

● Ready 3 days Training program ( HRDC claimable ) formulated for users to learn and work on any of the suitable AI applications at the work environments or processes.

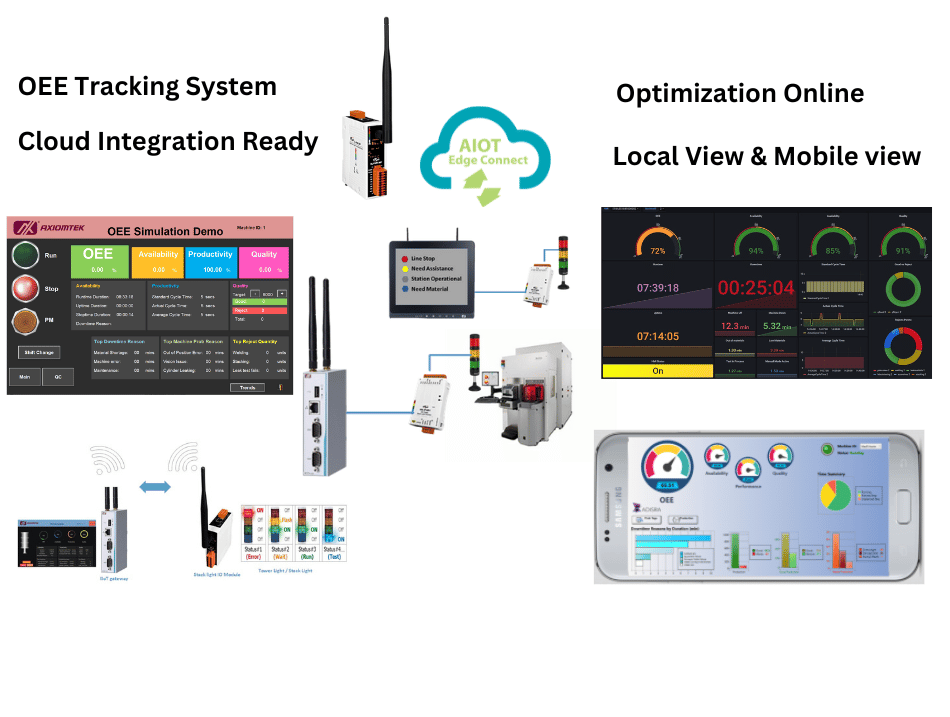

AIOT OEE INSIGHT CONNECT - OEE Tracking Suite Hybrid & Local Cloud Ready

AIOT OEE INSIGHT CONNECT:

Optimize Your Operations with Comprehensive OEE Tracking

AIOT OEE CONNECT is an advanced OEE (Overall Equipment Effectiveness) Tracking Suite designed to monitor and enhance the performance of various machines and processes. By capturing critical data such as Availability, Performance, and Quality, AIOT OEE CONNECT provides valuable insights to improve efficiency and productivity.

Key Components of AIOT OEE CONNECT:

Data Collection

Stack Light Module: Interface for machines equipped with stack lights.

Direct Signal Bridge-Machine Module: For machines without tower lights.

Direct Interface to PLC: Seamless integration with Programmable Logic Controllers (PLCs).

Vision AI QC Checkpoint: Advanced AI for quality control and data tracking.

Local IIoT Edge Gateway / Edge HMI Module

Data Gathering and Manipulation: Collect and process data locally.

Data Exchange: Interface with local SCADA or cloud systems.

Local SCADA / AIOT Cloud Platform

Local Data Dashboard: Real-time data visualization.

Logging and Reporting: Detailed data history and analysis.

Cloud Dashboard: Accessible data visualization and reporting from the cloud.

Data Historian: Long-term data storage and retrieval.

Features of AIOT OEE CONNECT:

- Tower Light Interface: Supports 3-6 color configurations for flexible monitoring.

- IO Bridge Module: Integration for exceptional cases.

- Vision AI for QC: Advanced AI for quality control and data tracking.

- PLC Protocol Support: Compatible with various market PLC protocols.

- Ready IIoT Gateway/HMI Template: Pre-configured templates for quick setup.

- Local Database Support: Compatible with SQL, Postgres, and Oracle.

- Cloud Dashboard Template: Pre-configured for easy cloud integration.

- Alert Messaging: Email, WhatsApp, and Telegram alerts for timely notifications.

- Smartphone Viewing: Mobile access for remote monitoring.

- MES/ERP Integration: Seamless integration via Web API.

- HRDC Training: Ready for 2-3 days of Human Resource Development Corporation (HRDC) training.

Benefits of OEE Tracking with AIOT OEE CONNECT:

Increased Equipment Availability: Minimize downtime through real-time monitoring and proactive maintenance.

Enhanced Performance: Optimize machine efficiency by identifying and addressing performance bottlenecks.

Improved Quality: Reduce defects and improve product quality with precise tracking and AI-driven quality control.

Data-Driven Decisions: Leverage comprehensive data and analytics to make informed decisions and drive continuous improvement.

Scalability and Flexibility: Adaptable to various machines and processes, ensuring seamless integration and scalability.

Cost Savings: Enhance productivity and reduce operational costs by maximizing overall equipment effectiveness.

Transform your manufacturing operations with AIOT OEE INSIGNT CONNECT. Gain unparalleled insights, improve efficiency, and drive productivity with our comprehensive OEE tracking suite. Contact us today to learn more and schedule a demo.

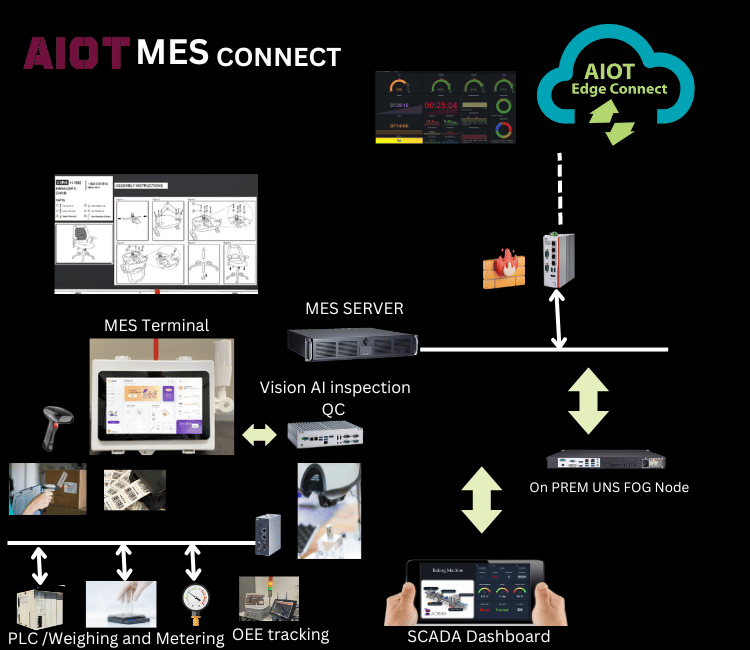

AIOT MES CONNECT

AIOT MES CONNECT:

Transforming SME Manufacturing Efficiency

Welcome to AIOT MES CONNECT, a comprehensive solution tailored for small and medium-sized enterprises (SMEs) to streamline manufacturing operations, enhance productivity, and ensure superior product quality. Integrating seamlessly with our AIOT EDGE Connect Cloud and AIOT OEE Connect for detailed OEE tracking, AIOT MES CONNECT empowers you with the tools needed to thrive in today’s competitive market.

Key Features of AIOT MES CONNECT

1. Production Management

Efficient production management is the backbone of any manufacturing operation. AIOT MES CONNECT offers robust tools to plan, schedule, and optimize your production processes, ensuring optimal use of resources and timely delivery.

Production Scheduling: Plan and adjust production schedules in real-time to meet changing demands.

Work Order Management: Automate and track work orders from creation to completion, ensuring every task is executed as planned.

Resource Allocation: Allocate labor, machinery, and materials effectively to maximize productivity.

2. Inventory Management

Effective inventory management is crucial for reducing costs and avoiding production delays. AIOT MES CONNECT provides real-time tracking and control of your inventory to ensure you always have the right materials at the right time.

Real-Time Materials Tracking: Monitor raw materials, work-in-progress (WIP), and finished goods in real-time.

Inventory Control: Manage stock levels efficiently, preventing shortages and overstock situations.

Lot and Serial Number Tracking: Ensure full traceability of materials and products throughout the supply chain.

3. Quality Management

Maintaining high-quality standards is essential for customer satisfaction and regulatory compliance. AIOT MES CONNECT integrates comprehensive quality management tools to monitor and control quality throughout the production process.

Quality Control: Conduct real-time quality inspections and record quality data at every production stage.

Non-Conformance Management: Identify, log, and manage defects or deviations to maintain high-quality standards.

Statistical Process Control (SPC): Utilize statistical methods to monitor and control production processes.

4. Production Tracking and Reporting

Gain real-time insights into your production processes with AIOT MES CONNECT. Monitor key performance indicators (KPIs) and generate detailed reports to make informed decisions and optimize operations.

Real-Time Data Collection: Capture data from machines and operators to monitor production activities in real-time.

Performance Metrics: Calculate KPIs such as yield, scrap rates, and machine uptime for comprehensive performance analysis.

Reporting and Analytics: Generate detailed reports and visual dashboards to analyze data trends and improve decision-making.

5. Maintenance Management (CMMS)

Proactive maintenance is vital for minimizing downtime and extending the lifespan of your equipment. AIOT MES CONNECT offers advanced maintenance management features to keep your operations running smoothly.

Preventive Maintenance Scheduling: Schedule regular maintenance tasks to prevent unexpected equipment failures.

Predictive Maintenance: Use data analytics to predict and address potential equipment issues before they occur.

Maintenance Work Order Management: Create and track maintenance work orders to ensure timely and effective maintenance activities.

6. Data Integration and Connectivity

Ensure seamless data flow and integration with other systems using AIOT MES CONNECT. Our solution supports connectivity with various enterprise systems and IoT devices for comprehensive operational visibility.

ERP Integration: Integrate with Enterprise Resource Planning (ERP) systems for coordinated operations and data exchange.

IoT Connectivity: Connect to IoT sensors and devices for real-time data collection and monitoring.

APIs and Interfaces: Utilize open APIs for custom integrations and seamless data exchange with other applications.

Why Choose AIOT MES CONNECT?

AIOT MES CONNECT is designed to meet the unique needs of SMEs, providing powerful tools to enhance manufacturing efficiency, improve quality, and reduce costs. By integrating with our AIOT EDGE Connect Cloud and AIOT OEE Connect, you gain a unified solution that offers real-time insights and detailed tracking for optimal operational performance.

Transform your manufacturing operations with AIOT MES CONNECT. Contact us today to learn more and schedule a demo.

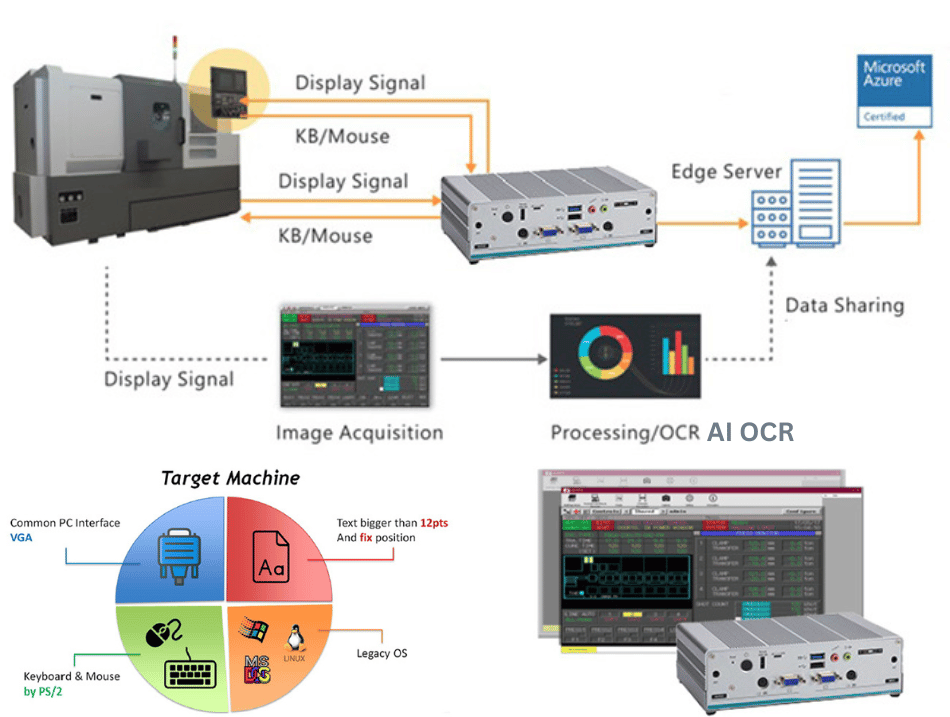

AIOT NON-INTRUSIVE CONNECT

- AIoT NON-INTRUSIVE CONNECT is one of the solutions provided by AIoTmission where data can be extracted by way of an external vision camera to the subject of extraction or pictures and videos of the subject that feed into an AI engine for extraction. The non-intrusive part is that there is no tempering of the existing system or no additional sensors added to the subject matter by way of any wiring connection. However, the data can still be extracted accurately and effectively.

The applications of these solutions are:–

- legacy equipment that doesn’t allow any connectivity option.

- Legacy Mimic display panel that doesn’t allow any connectivity option.

- analog gauges that do not have any form of digital connectivity.

and many more. The advantage of this solution:-

- Easy data extraction

- avoids the upgrading of legacy equipment that requires high cost.

- easy data extraction point

The data extraction online can then be published to the local SCADA dashboard or even the AIoT Edge Cloud platform for further data analytic and present.

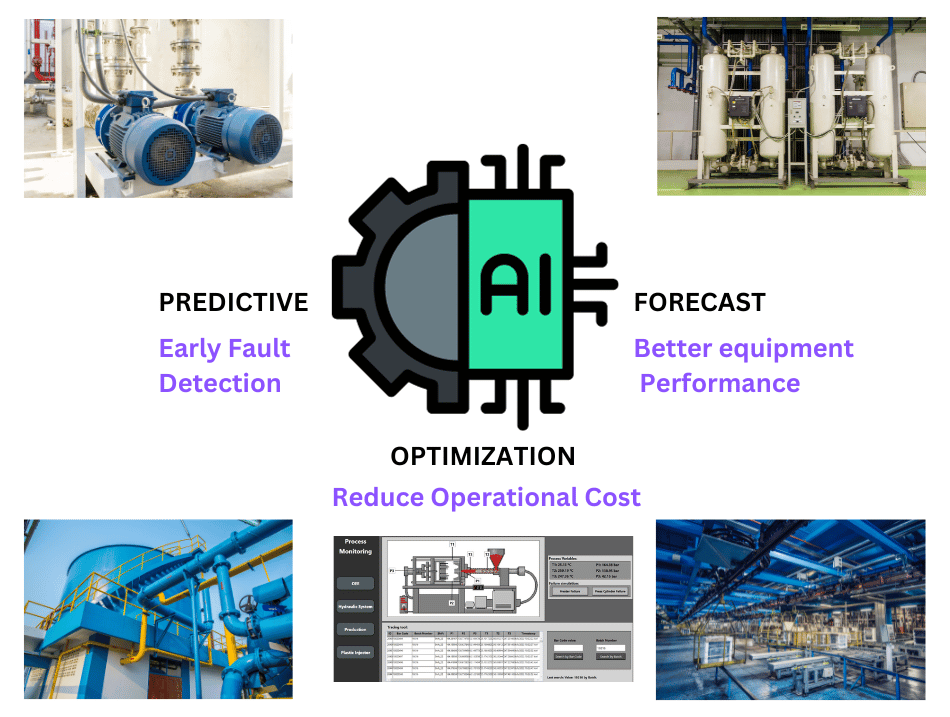

AIOT ANALYTIC CONNECT

AIOT ANALYTIC CONNECT

AIOT ANALYTIC CONNECT is a customized AI Data-Driven Solution for Optimizing, Forecasting, and Predictive Insights

In today’s rapidly evolving landscape, data is the cornerstone of informed decision-making. AIOT ANALYTIC CONNECT is your tailor-made solution, harnessing the power of AI and data analytics to revolutionize the way you operate in various domains, from manufacturing to utility management. With AIOT ANALYTIC CONNECT, you gain access to three key functions that can transform your operations: optimization, forecasting, and predictive analytics.

Optimization:

In the realm of manufacturing, efficiency is paramount. AIOT ANALYTIC CONNECT offers advanced optimization capabilities that streamline your production processes, reduce waste, and enhance resource utilization. By leveraging real-time data and AI algorithms, it identifies bottlenecks, minimizes downtime, and fine-tunes your operations for maximum output, ultimately increasing your competitiveness and profitability.

Forecasting:

Utility management, such as water distribution and energy management, demands foresight. AIOT ANALYTIC CONNECT excels in forecasting, offering a comprehensive view of future trends and demands. With its data-driven approach, it empowers you to make proactive decisions, ensuring resource availability, reducing costs, and improving customer satisfaction. Whether it’s predicting energy consumption patterns or optimizing water distribution networks, AIOT ANALYTIC CONNECT is your trusted partner in future-proofing your utility management.

Predictive Analytics:

For sustainable growth, you need to anticipate challenges and opportunities. AIOT ANALYTIC CONNECT offers predictive analytics that delve deep into historical and real-time data, unveiling insights that help you plan for the future. Whether it’s predicting maintenance needs for machinery in manufacturing or identifying potential grid failures in energy management, our solution gives you the edge in staying ahead of the curve.

AIOT ANALYTIC CONNECT is versatile, adapting seamlessly to your specific needs and challenges. Its intuitive interface and actionable insights empower your teams to make data-informed decisions effortlessly. Say goodbye to uncertainty, inefficiency, and reactive problem-solving.

Experience the transformative power of AIOT ANALYTIC CONNECT across manufacturing and utility management domains. Embrace a data-driven future, reduce costs, and enhance your competitiveness. With our solution, you’re not just keeping pace with the changing landscape; you’re setting the standards for excellence.

Choose AIOT ANALYTIC CONNECT and lead the way in the data-driven revolution.