Productivity through Digitalization

Plugfest 1.0 & 2.0: A Gateway to Malaysia’s Industrial 4.0 Transformation

The Plugfest programs, driven by the Malaysia Productivity Corporation (MPC) and the Electrical and Electronics Productivity Nexus (EEPN), have played a key role in advancing Malaysia’s Industry 4.0 journey. These programs are structured to offer hands-on training and real-world applications in two critical domains: Industrial Internet of Things (IIoT) in Plugfest 1.0, and AI-based Internet of Things (AIoT) in Plugfest 2.0. These workshops aim to equip SMEs and industrial players with the knowledge, skills, and technology required to enhance productivity, streamline operations, and maintain competitiveness in the digital era. Full detail of the program can be referred via this link.

Axiomtek, a trusted leader in industrial computing, has been an integral part of both Plugfest programs, supplying high-performance hardware and software platforms that power many of the hands-on activities and Proof-of-Concept (POC) projects developed by participants. Through its subsidiary AIoTmission Sdn Bhd, Axiomtek has also contributed to refining these programs into practical solutions tailored to meet the needs of Malaysia’s manufacturing sector.

PLUGFEST 1.0 - Industrial IOT

Plugfest 1.0: Empowering Industries with IIoT

Plugfest 1.0 served as an introduction to Industrial Internet of Things (IIoT) for SMEs and larger companies in Malaysia. The primary goal was to train participants to harness the power of real-time data acquisition and monitoring, connecting industrial devices to digital platforms. This allows for enhanced visibility, control, and optimization of manufacturing processes.

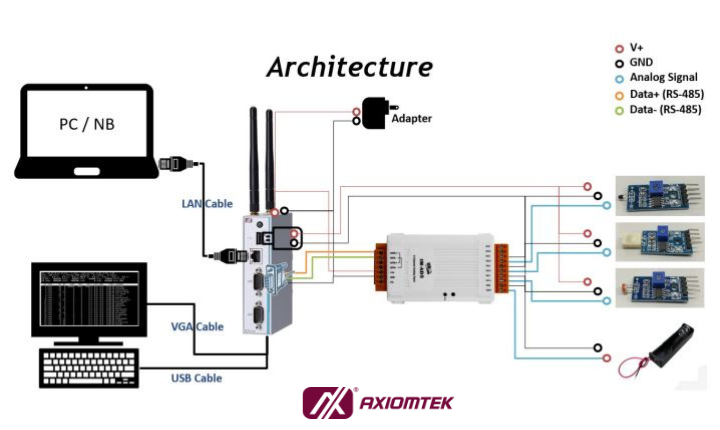

Program Structure and Technologies: Participants were trained to connect sensors—such as light, temperature, and humidity sensors—to an analog-to-digital converter (ADC), which was further connected to an Internet Gateway. Using Node-RED programming, participants learned how to visualize the sensor data on interactive dashboards, enabling real-time decision-making.

Axiomtek’s Role: Axiomtek’s industrial-grade hardware played a pivotal role in ensuring the smooth execution of Plugfest 1.0. The company provided high-performance industrial PCs and edge computing platforms, which were responsible for collecting and processing sensor data from multiple sources. These robust solutions allowed participants to experience how IIoT applications can be seamlessly integrated into real industrial environments.

Through this involvement, Axiomtek’s hardware demonstrated its reliability in handling IIoT workloads, supporting multiple connected devices, and ensuring stable data transmission between systems. This not only improved the learning experience but also showcased the scalability and industrial applicability of IIoT for the Malaysian manufacturing sector.

Outcomes and Applications: By the end of Plugfest 1.0, participants had developed multiple POCs that applied IIoT solutions to improve operations within their organizations. These POCs included real-time monitoring systems for environmental conditions (e.g., temperature and humidity in production lines) and equipment maintenance, such as remote monitoring and early detection of machine issues.

Companies that adopted these solutions benefited from improved operational efficiency, reduced downtime, and the ability to make data-driven decisions. The success of Plugfest 1.0 demonstrated that IIoT is a powerful tool for boosting productivity and ensuring continuous improvement in industrial environments.

PLUGFEST 2.0 - AIS / AIOT

Plugfest 2.0: Scaling with AI and IoT for Smart Manufacturing

Following the success of Plugfest 1.0, Plugfest 2.0 raised the bar by introducing the participants to the next frontier: AI-based IoT (AIoT). This program focused on how artificial intelligence, coupled with IoT technologies, could revolutionize the way manufacturers monitor, analyze, and optimize production processes. The fusion of AI and IoT enables businesses to implement smart automation, predictive maintenance, and real-time defect detection systems, all critical to modern manufacturing environments.

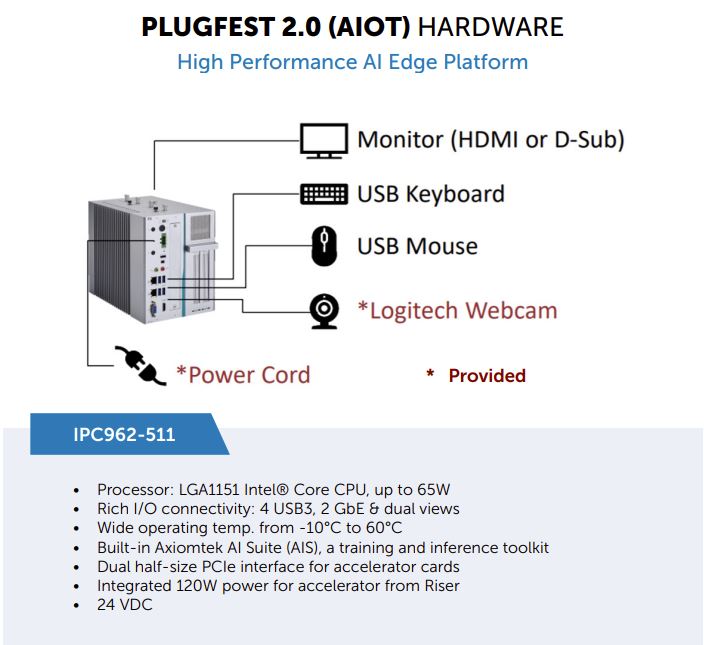

Program Structure and Technologies: Participants were equipped with an Intel-based industrial PC powered by Intel Edge Insights for Industrial and the Intel OpenVINO toolkit. Over the course of six days, participants learned how to implement machine learning algorithms and develop AI models to automate quality inspections, detect defects, and even predict equipment failure.

Through AI-based image recognition systems, participants were trained to label and detect anomalies in manufacturing processes, creating real-time inferencing systems that could automatically identify errors and optimize workflows.

Axiomtek’s Role: Axiomtek’s AIoT platforms were a cornerstone of Plugfest 2.0. The company’s high-performance hardware not only handled the complex AI inferencing tasks but also processed large amounts of data generated by IoT sensors and cameras in real time. Axiomtek’s edge computing solutions enabled participants to run AI models directly on the shop floor, significantly reducing latency and ensuring faster response times during production.

Moreover, Axiomtek’s solutions offered the flexibility and scalability required for both small-scale operations and large manufacturing setups, ensuring that businesses of all sizes could benefit from AIoT technologies. This versatility allowed the participants to deploy AIoT solutions in various real-world scenarios, from predictive maintenance to automated defect detection in assembly lines.

Outcomes and Industrial Impact: Plugfest 2.0 enabled participating companies to implement smart factory solutions that reduced human error, improved quality control, and increased overall equipment effectiveness (OEE). For instance, some companies were able to automate the inspection of microchips and electronic components, ensuring faster and more accurate defect detection. Others implemented predictive maintenance systems that leveraged AI algorithms to foresee equipment malfunctions, thereby avoiding costly downtime.

These outcomes demonstrated the transformative potential of AIoT in Malaysia’s manufacturing landscape, positioning Axiomtek as a key enabler in the country’s Industry 4.0 revolution.

Axiomtek’s Broader Vision: Practical Solutions for Industrial Transformation

Axiomtek has taken the lessons learned from the Plugfest programs and refined them into industrially viable solutions that cater to the specific needs of Malaysian manufacturers. Through its subsidiary, AIoTmission Sdn Bhd, Axiomtek continues to support the adoption of AI and IoT technologies across various industries, ensuring that companies can accelerate their digital transformation journeys.

Key Innovations:

- AIoT Integration: By combining AI with IoT, Axiomtek’s platforms offer real-time analytics and automated decision-making, allowing industries to optimize processes, reduce waste, and improve product quality.

- Scalability: Axiomtek’s solutions are designed to be scalable, making them suitable for SMEs as well as large enterprises. This flexibility ensures that businesses of all sizes can embrace Industry 4.0 technologies at their own pace.

- Practical Implementation: Beyond the workshops, Axiomtek’s hardware and AIoT platforms have been deployed in real-world settings, offering proven solutions for smart manufacturing, predictive maintenance, and overall operational efficiency.

The Plugfest programs, with Axiomtek’s active participation, have served as a launchpad for Malaysia’s transition to Industry 4.0. By providing robust, scalable, and intelligent hardware solutions, Axiomtek has not only supported the success of these programs but also helped businesses realize the potential of IIoT and AIoT technologies. As Malaysian industries continue to evolve, Axiomtek remains at the forefront, driving industrial transformation with its commitment to innovation and practical applications of cutting-edge technology.

This version offers a concise yet detailed explanation of the Plugfest 1.0 and 2.0 programs, along with Axiomtek’s role in making them successful, emphasizing how the company has made these initiatives practical and scalable for industrial transformation.

Both the program are made a industrial practical model that covers almost all applications that related to Shop floor data acquisition, manipulation and many computer vision deep learning AI at the manufacturing process. Currently AIoTmission Sdn Bhd is driving this initiative that provide a smooth transition of digitalization in the IR4 adoption for smart manufacturing.

For Some Proof of concepts and applications created by the attendees during the PlugFest Training program can be found in the News section of Plugfest at Axiomtek website.