Applying Industrial IoT and AI in power measurement and optimization

Introduction to Power Measurement with Industrial IoT and AI in Predictive Power Management

In today’s rapidly evolving industrial landscape, effective power management is crucial for optimizing operational efficiency, reducing costs, and minimizing environmental impact. Traditional methods of power measurement and management often fall short in providing real-time insights, predictive capabilities, and the adaptability needed to address the complexities of modern industrial environments. This is where Industrial Internet of Things (IIoT) and Artificial Intelligence (AI) come into play, revolutionizing the way industries monitor, manage, and optimize their energy consumption.

Power Measurement with Industrial IoT

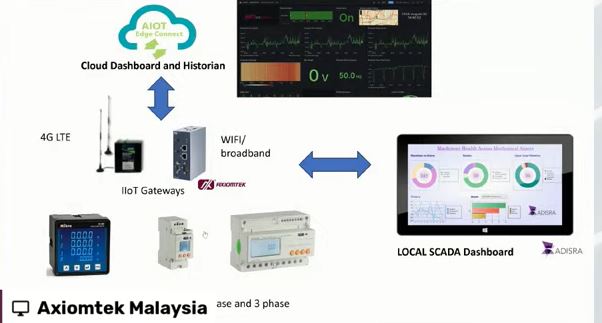

The Industrial Internet of Things (IIoT) refers to the integration of interconnected sensors, devices, and systems within industrial settings, enabling the collection and exchange of vast amounts of data in real time. When applied to power measurement, IIoT allows for the continuous monitoring of electrical parameters—such as voltage, current, power factor, and energy consumption—across various equipment, machinery, and processes.

Key benefits of IIoT in power measurement include:

Real-Time Monitoring: IIoT-enabled sensors provide continuous, real-time data on power usage, enabling industries to identify inefficiencies, detect anomalies, and monitor the health of electrical systems instantaneously.

Data Granularity: Detailed data from IIoT devices allow for granular insights into energy usage patterns, down to individual machines or processes, facilitating targeted energy-saving measures.

Remote Accessibility: Power data collected by IIoT devices can be accessed remotely through cloud platforms, allowing plant managers and engineers to monitor and manage power usage from anywhere.

Scalability: IIoT systems can be easily scaled to accommodate additional sensors and devices as needed, making them suitable for both small-scale facilities and large industrial complexes.

AI in Predictive Power Management

While IIoT provides the data foundation, Artificial Intelligence (AI) leverages this data to unlock advanced predictive power management capabilities. AI algorithms, particularly those involving machine learning and predictive analytics, can analyze historical and real-time power data to forecast future energy needs, detect potential equipment failures, and optimize energy usage.

Here’s how AI enhances predictive power management:

Predictive Maintenance: AI algorithms can predict when equipment is likely to fail based on patterns in power usage data. By identifying potential issues before they lead to downtime, industries can schedule maintenance proactively, reducing unexpected disruptions and extending equipment life.

Energy Demand Forecasting: AI can analyze past energy consumption trends, production schedules, and external factors (like weather) to forecast future power needs accurately. This enables better planning and purchasing of energy resources, reducing costs and ensuring a stable power supply.

Anomaly Detection: AI-driven analytics can detect anomalies in power usage that might indicate inefficiencies, faults, or unauthorized energy use. By identifying these anomalies early, industries can take corrective actions promptly, avoiding energy wastage and potential hazards.

Optimization of Energy Usage: AI can optimize energy usage by dynamically adjusting processes and operations based on real-time data. For example, AI can reduce energy consumption during peak demand times or shift loads to take advantage of lower energy rates, thereby lowering overall energy costs.

Sustainability and Compliance: AI can assist in meeting sustainability goals by optimizing energy consumption patterns to reduce carbon emissions. It can also help industries comply with energy regulations by monitoring and reporting power usage metrics against regulatory standards.

Conclusion

The integration of IIoT and AI in power measurement and management represents a significant advancement in industrial operations. By providing real-time insights, predictive capabilities, and optimization strategies, these technologies enable industries to not only improve their energy.