AIoT Live session 7 on AIOT SCADA Integration

In the 7th ” Sembang” AIoT session, CC Lee shared the topic about the SCADA Vs IIoT where there are many areas of overlaping between the SCADA and IIoT ( industrial IoT) at the same time they have their differences.

Both SCADA (Supervisory Control and Data Acquisition) and IIoT (Industrial Internet of Things) are technologies that allow for data acquisition, monitoring, and control, but they are different in terms of architecture, scalability, and their typical use-cases.

1. Use Cases: SCADA systems are traditionally used in industrial processes for controlling large-scale processes where data from multiple sensors is combined and analyzed in real time. Common applications include Kl no water treatment plants, power generation, and oil and gas refineries. On the other hand, IoT is a more general concept that can be applied in numerous scenarios, not limited to industrial processes. It’s widely used in smart homes, healthcare, agriculture, and urban infrastructure, among others.

2. Architecture: SCADA systems typically have a centralized architecture with all the data flowing to a single central location for processing and control. IoT, however, often operates on a decentralized architecture where data can be processed and actions taken at the edge, closer to the source of the data.

3. Scalability: SCADA systems are usually designed for specific purposes and their scalability can be limited. IoT, due to its flexible and modular nature, can be easily scaled up or down depending on the application.

4. Connectivity: SCADA systems traditionally use a closed, private network for security and reliability reasons, whereas IoT devices are often connected to the internet, making them potentially more vulnerable to cyber-attacks but also more accessible and capable of integration with other systems and technologies.

5. Data Handling: SCADA systems focus more on real-time control and less on data analysis and prediction. IoT, on the other hand, leverages cloud computing and big data analytics, enabling not only real-time control but also predictive maintenance and other advanced features.

In the modern industrial landscape, these two technologies often work together. Many companies are integrating IoT devices into their SCADA systems to enhance data collection and analysis capabilities.

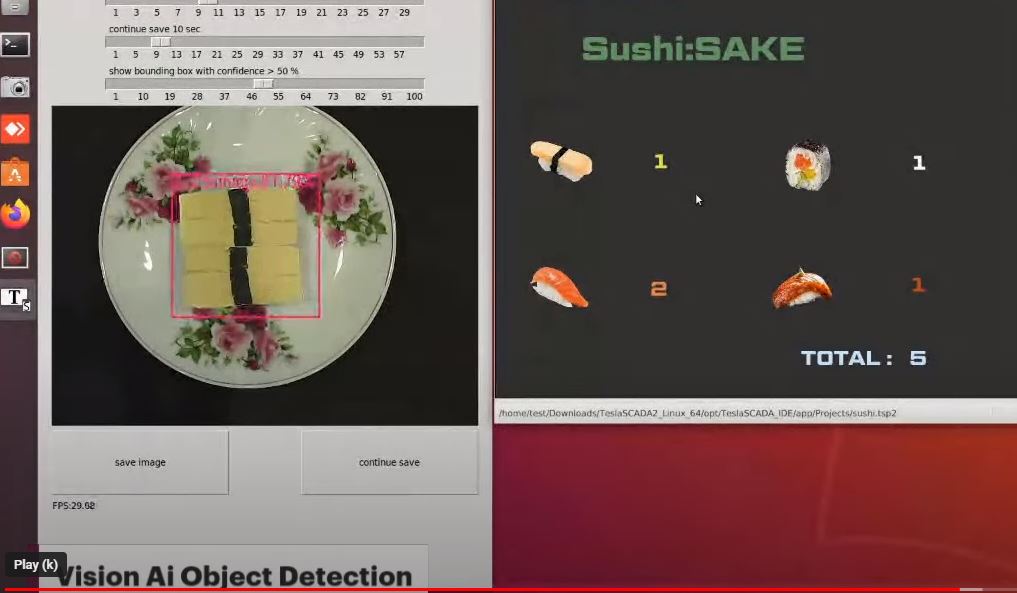

Demonstration on Vision AI Object detection

Live demonstration on object detection on the type of Sushi on a conveyor belt moving. the AI model was built using the Mobilenet V2.

AI data was captured and pushed to the SCADA system within the system to indicate the counting of the type of sushi passing through the conveyor belt.

The Vision AI operation in this case was powered by Axiomtek industrial PC with a very affortable web camera system.

To watch the live session, please visit the link below:-

https://www.youtube.com/watch?v=6wmwtmc28Bk