Unlocking the Future of Manufacturing with AI and IoT: Axiomtek’s Latest Breakthrough

Welcome back to Sembang AIoT, your go-to source for all things AI and IoT! In our 20th edition, we’re about to embark on an exciting journey where technology meets innovation. Axiomtek Malaysia with AIoTmission has just unveiled a game-changing revelation, one that’s set to redefine the landscape of manufacturing and beyond.

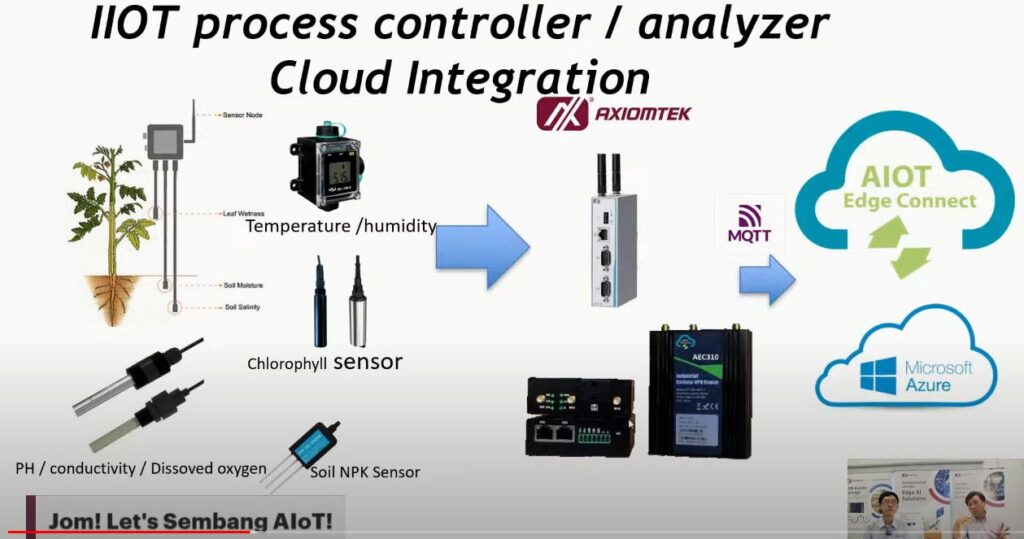

We’ve got more in store for you, and this time, it’s all about the Internet of Things (IoT) sensors, specifically tailored for Smart Agriculture. We’re talking about a lineup of sensors that includes everything from pH and salinity sensors to soil NPK sensors, temperature gauges, and humidity detectors. What makes these sensors even more remarkable is that they can seamlessly communicate and relay data to the AIoT Edge Connect Cloud, local OPCUA servers, local Web APIs, or even web servers, making data accessibility easier than ever before.

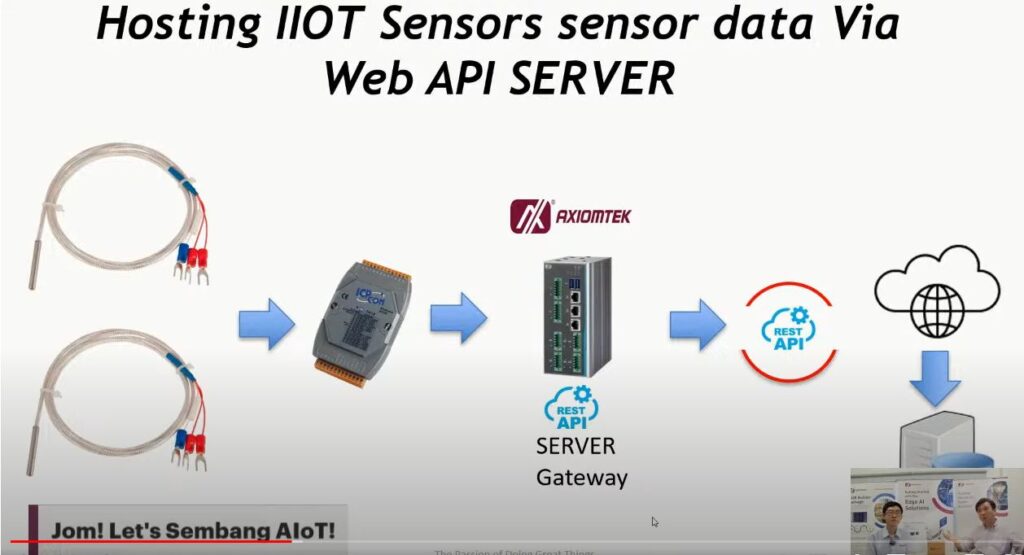

But the real magic happens when you witness our Axiomtek IIoT Edge Gateway in action. This powerful device not only collects data from the RTD Temperature module and various sensors but also logs this valuable information at the edge gateway. The data isn’t just stashed away; it’s sent to a Web API or Rest API server, residing right on the Edge Gateway.

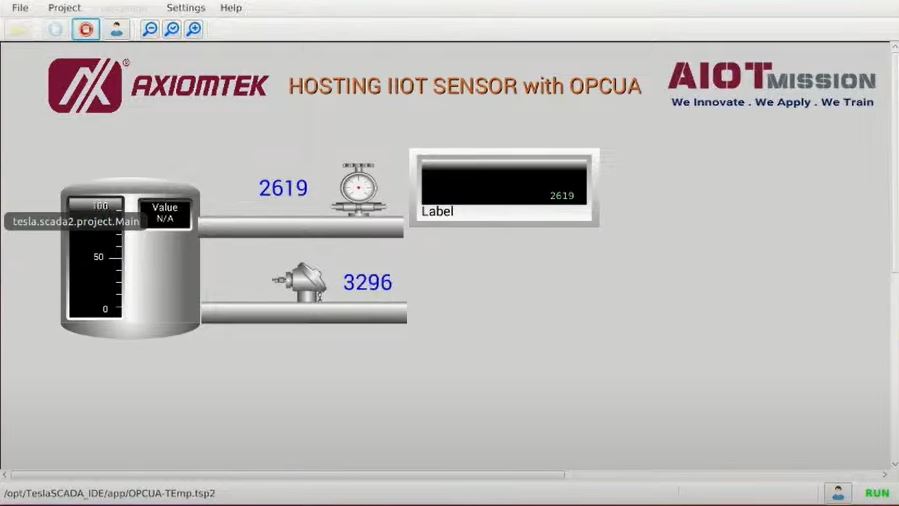

Now, imagine this scenario: you’re miles away from the production floor, perhaps in another corner of the factory or even off-site. You need real-time data, and you need it now. That’s where our Adisra IIoT SCADA software comes into play. It’s designed to seamlessly connect to the Web API server, enabling you to access live data online. Plus, you have the power to schedule data retrieval as frequently as needed. Need updates every second? No problem, we’ve got you covered.

At the core of this innovation is the idea that data is not just information but a valuable resource that can transform the way we manufacture, manage, and optimize processes. With Axiomtek’s cutting-edge technologies, you’re not just embracing the future; you’re shaping it.

Axiomtek IIoT edge gateway is hosting the data polled, in this case, 2 x RTD sensors data from the RTD module were obtained. Local display on the temperature was shown on the gateway as an option nevertheless the IIoT edge gateway can be a stand alone headless if you want it to be.

The right hand picture showed on another IPC running Adisra SCADA software with Web API client driver where the http get can be done in a quite straightforward manner.

In this demo, we only apply user name and password to connect to the Web API server although it supports token + User name+ Password as well.

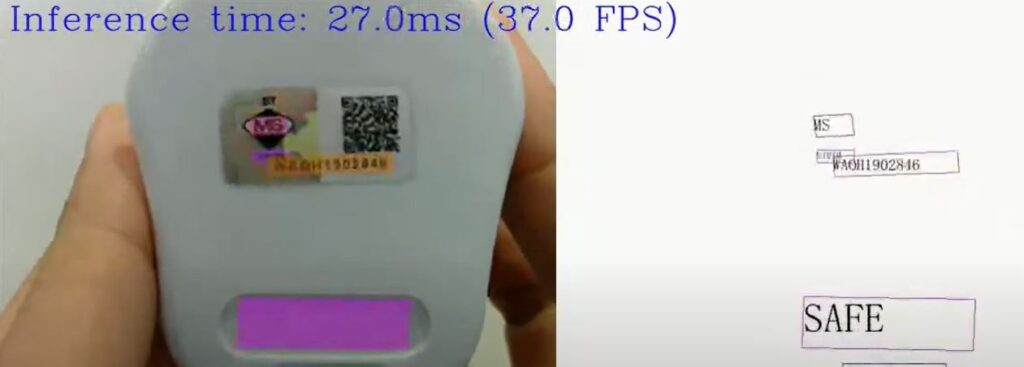

The latter part of the presentation commenced by delving into the AI OCR model, offering insights into its background and development. We are leveraging a highly efficient model capable of optical character recognition (OCR) through computer vision, primarily focusing on two key objects adorned with printed characters. These objects include the “Sirim” sticker found on a 3-PIN power plug and the printed content on the Axiomtek carton box.

Picture this: Real Vision OCR (Optical Character Recognition) powered by the formidable OpenVINO AI engine from Intel, all seamlessly integrated into the groundbreaking Axiomtek AI Edge Platform..

Sirim STandard approval sticker on Vision AI camera. Character read and recorded

AI OCR (Artificial Intelligence Optical Character Recognition) has several applications in the manufacturing industry, where it can improve efficiency, accuracy, and automation. Here are some key applications of AI OCR in manufacturing:

1. Quality Control and Inspection:

– AI OCR can be used to inspect product labels, barcodes, serial numbers, and other critical information to ensure they meet quality standards.

– It can identify defects or discrepancies in printed labels or packaging, helping to reduce product recalls and maintain quality control.

2. Inventory Management:

– AI OCR can automate the process of tracking and managing inventory by recognizing and updating product information from labels and packaging.

– It can help prevent overstocking or understocking of items and improve supply chain management.

3. Document Management:

– Manufacturers deal with various documents, such as invoices, purchase orders, and shipping labels. AI OCR can automate the extraction and digitization of data from these documents.

– This improves accuracy and reduces manual data entry, saving time and reducing errors.

4. Equipment Maintenance:

– AI OCR can be used to read and interpret data from equipment sensors and gauges, allowing for predictive maintenance.

– By analyzing this data, AI systems can predict when machinery needs maintenance or repairs, reducing downtime and maintenance costs.

5. Regulatory Compliance:

– Manufacturers often need to comply with various regulatory standards and certifications. AI OCR can assist in the verification and validation of documents and labels to ensure compliance.

– It can flag discrepancies or missing information that could lead to compliance issues.

6. Traceability and Serialization:

– In industries like pharmaceuticals and food production, traceability is crucial. AI OCR can help in tracking and tracing products throughout the manufacturing process.

– It can read and verify serial numbers, lot codes, and other identifiers to ensure product authenticity and traceability.

7. Supplier and Vendor Management:

– AI OCR can automate the verification of supplier and vendor invoices, ensuring that they match the agreed-upon terms and quantities.

– It can also help in tracking payments and managing accounts payable more efficiently.

8. Maintenance and Repair Manuals:

– AI OCR can convert printed maintenance and repair manuals into digital formats, making it easier for technicians to access and search for information.

– It can also be used to extract relevant data from these manuals for troubleshooting and repair purposes.

9. Energy Management:

– Manufacturers can use AI OCR to monitor energy consumption by reading and analyzing utility bills and meter data.

– This information can help in optimizing energy usage and reducing operational costs.

10. Labeling and Packaging:

– AI OCR can assist in automated labeling and packaging processes, ensuring that labels are applied accurately and products are packaged correctly.

– It can also check for alignment, print quality, and the presence of required information on product packaging.

In summary, AI OCR plays a vital role in streamlining various aspects of manufacturing, from quality control and inventory management to compliance and documentation. It enhances efficiency, reduces errors, and contributes to overall cost savings in the manufacturing industry.

Watching us live or future live session by subscribing to our youtube channel below:-

https://youtube.com/live/FXHJZn2J3Fs