OEE 6 Big losses -The Small Stop

While it is SMALL, it can also be very BIG! 🤪 There we go again …

6 Big OEE losses #4-The Small Stop

Best way to understand small stop is like traveling on a journey towards a destination, along the way, you are estimating to reach the destination say in 1 hour, along the road

you bump into a traffic jam, road blockages, accidents etc. These are the small stops.

In the production process, minor disruptions often occur due to waiting for materials to run, delay in restarting machines after the disruption, equipment misalignment, or jam-ups. These are the common small stops that we have been focusing on.

Some advance processes have built-in functions that detect the cause of these stops. These systems may rely on Stack light indicator or internal controller like PLCs to detect error codes related to the disruption. Why are these small stops important? As you know when the production is running 24 hours daily, all these seemingly minor stops will accumulate over time then contributing to the big losses. Despite being called “small”, they are indeed a key contributing factor to the 6 big losses.

While some advance machines are capable of detecting and logging stop codes, many legacy machines do not have this capability. As a result, the small stop in production are often neglected, ultimately leading to major inefficiencies in the process.

There are several ways to track small stops in production. One of them involves connecting to the machine controller or sensing events through the tower light whenever the machine experiences a small stop. But, that doesn’t end there, the most effective approach is still to provide a user interface for the operators, allowing them to identify and record what happened by disruption error code. These codes, along with their corresponding time intervals, are then used in reports or analyses to identify frequently occurring issues and drive improvements aimed at minimizing disruptions.

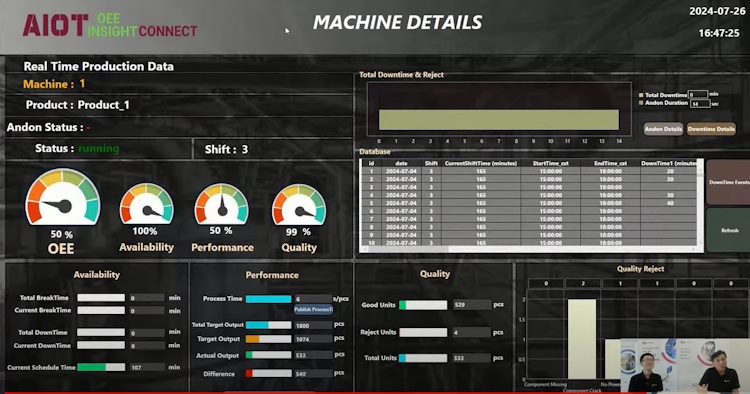

There are several good solution for tracking these stops, one of them is the stack light tracker, which records the status of the indicator lights in a combination and the previous state, current state of accumulated time taken. That doesn’t end there, integrating a good compact sized Axiomtek graphical Operator Terminal with Adisra Smart view HMI software tool is a cost-effective way to collect and visualize all the relevant data.

Finally, when extending this to an Industrial IoT (IIoT) cloud-based solution—such as ADISRA’s InsightView—data can be monitored in real time through a dashboard featuring analytical reports. By leveraging AI analytics, machine learning, or rule-based actions, optimization and efficiency can be taken to the next level.

#aiotmission #aiotoeeinsightconnect #oeeinsight #aiot #aiotanalyticconnect #unplanneddowntime