Industrial Robots for Smart Manufacturing

Smart manufacturing integrates advanced technologies, including robotics, to optimize processes, improve efficiency, and enhance flexibility. Several types of robots are utilized in smart manufacturing to achieve these goals. Here are some key types:

Industrial Robots: These robots are versatile and programmable machines used for various manufacturing tasks, such as welding, assembly, material handling, and packaging. They are equipped with sensors, vision systems, and sometimes AI algorithms to adapt to changing conditions and interact with other machines or humans.

Collaborative Robots (Cobots): Cobots are designed to work alongside humans in a shared workspace safely. They typically feature advanced safety features and are used for tasks that require close collaboration between humans and machines, such as assembly, inspection, and testing.

Mobile Robots: Mobile robots, including Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), navigate autonomously within a manufacturing facility to transport materials, components, or finished products between different locations. They optimize logistics processes and increase flexibility in material handling.

3D Printing Robots: Also known as additive manufacturing robots, these machines create three-dimensional objects by depositing material layer by layer. They are used in smart manufacturing for rapid prototyping, customization, and production of complex geometries with reduced material waste.

AGVs with Manipulators: Some AGVs are equipped with robotic arms or manipulators to handle tasks such as picking, placing, or manipulating objects within a manufacturing facility. These hybrid systems combine the mobility of AGVs with the flexibility of robotic manipulation.

Industrial robots play a crucial role in improving productivity and efficiency in manufacturing and industrial processes in several ways:

Automation of Repetitive Tasks: Industrial robots excel at performing repetitive tasks with high speed and precision, reducing the need for manual labor. By automating these tasks, robots can operate continuously without breaks, leading to increased productivity.

Consistent Quality: Robots can execute tasks with consistent precision and accuracy, ensuring uniform quality in manufacturing processes. This consistency reduces the likelihood of defects or errors, leading to higher-quality products and fewer rework or scrap rates.

Increased Throughput: Robots can work at a faster pace than human workers in many cases, leading to higher throughput and production rates. This acceleration in production helps meet demand more efficiently and reduces lead times.

Improved Safety: Robots can be deployed in hazardous or physically demanding environments where it may be unsafe for humans to work. By taking on these tasks, robots enhance workplace safety and reduce the risk of accidents or injuries to human workers.

24/7 Operation: Unlike human workers who require rest periods, robots can operate continuously, enabling round-the-clock production schedules. This capability maximizes equipment utilization and minimizes idle time, thereby optimizing resource efficiency.

Flexibility and Adaptability: Many industrial robots are programmable and can be easily reconfigured or reprogrammed to perform different tasks or adapt to changes in production requirements. This flexibility allows manufacturers to quickly respond to market demands and product variations.

Reduced Cycle Times: Industrial robots can streamline manufacturing processes by minimizing cycle times for tasks such as assembly, machining, or material handling. This efficiency improvement leads to faster production cycles and shorter lead times for delivering products to customers.

Optimized Resource Utilization: By automating processes with robots, manufacturers can optimize resource utilization, including raw materials, energy, and labor. Robots are often more energy-efficient than traditional machinery, and their precise movements minimize material waste.

Data Collection and Analysis: Many modern industrial robots are equipped with sensors and connectivity features that enable data collection during operation. This data can be analyzed to identify opportunities for further efficiency improvements, predictive maintenance, or process optimization.

Overall, industrial robots contribute significantly to improving productivity and efficiency in manufacturing by automating tasks, ensuring consistent quality, increasing throughput, enhancing safety, and enabling flexibility in production processes

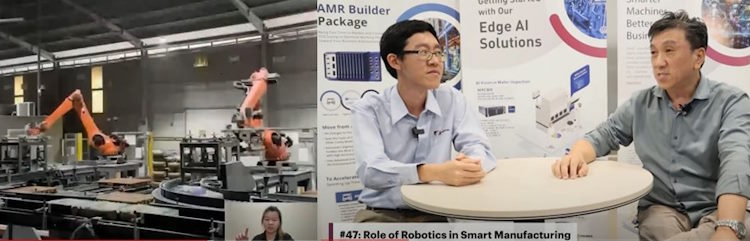

Sembang AIOT session this round brought to you by Mr. CC Lee and Tan Kien Loeng brought up an interview with a company who specialize in Palletizing Robotic Arm.

You may click the link below to find out more about it.

https://youtube.com/live/U8SFlQrcXvM