Sembang AIoT -IIoT and ESG

We have just come back from the Malaysia IoT association event on the empowering ESG with IoT. There is an open discussion in the event with the panelists like Dr. Ong Kian Ming, the ex Deputy Minister of international of trade, Mr. Steven Lim the president of ESG Malaysia and others. It was an informative session where ESG was touched at at a deeper level for the industries and how IoT can played the role in providing data that contribute to the framework of compliance of ESG for the companies.

ESG stands for Environmental, Social, and Governance, and it refers to a set of criteria used to evaluate a company’s performance in these three key areas. ESG has become an important framework for investors, businesses, and other stakeholders interested in assessing the sustainability and ethical impact of an organization.

1. Environmental (E): This aspect assesses a company’s impact on the environment and how it manages environmental risks. It includes considerations such as the company’s carbon footprint, energy efficiency, waste management, use of natural resources, and adherence to environmental regulations.

2. Social (S): The social component evaluates a company’s relationships with its employees, communities, customers, and other stakeholders. Social factors encompass issues like labor practices, diversity and inclusion, employee relations, community engagement, and the overall impact on society.

3. Governance (G): Governance focuses on the structure and effectiveness of a company’s leadership, management practices, and internal controls. Key governance factors include board composition, executive compensation, shareholder rights, transparency, and ethical business practices.

Investors and financial institutions increasingly consider ESG factors in their decision-making processes. Companies that perform well in ESG criteria are often viewed as more sustainable, responsible, and better positioned for long-term success. ESG considerations are not only driven by ethical concerns but also by the recognition that companies with strong ESG practices may be better positioned to manage risks, attract capital, and build positive relationships with stakeholders.

The integration of ESG principles has gained momentum globally, and various reporting standards and frameworks, such as the Global Reporting Initiative (GRI), Sustainability Accounting Standards Board (SASB), and Task Force on Climate-related Financial Disclosures (TCFD), provide guidelines for companies to disclose relevant ESG information in a standardized manner.

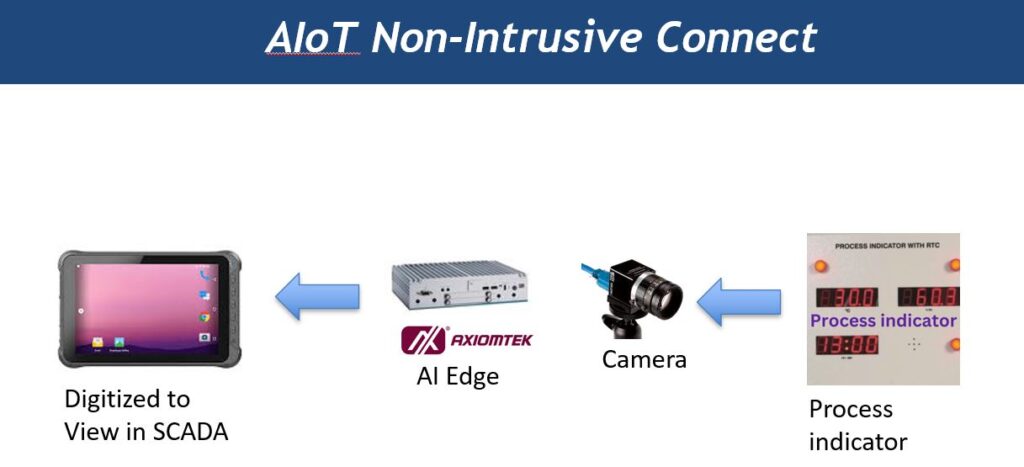

In the event, we took part in presenting Non intrusive Data Extraction with AI where as far as data collection is concern, this AIoT non-intrusive connect solutions from us can be fully utilized to obtain the data we want with least effort when it was assisted with the AI.

Two demos was presented :

1. Analogue gauge reading via AI

2. process display and indicators reading with Vision AI

Demonstration by Kien Leong during the event.

After data extraction, data can be published to cloud and link to the local SCADA system.

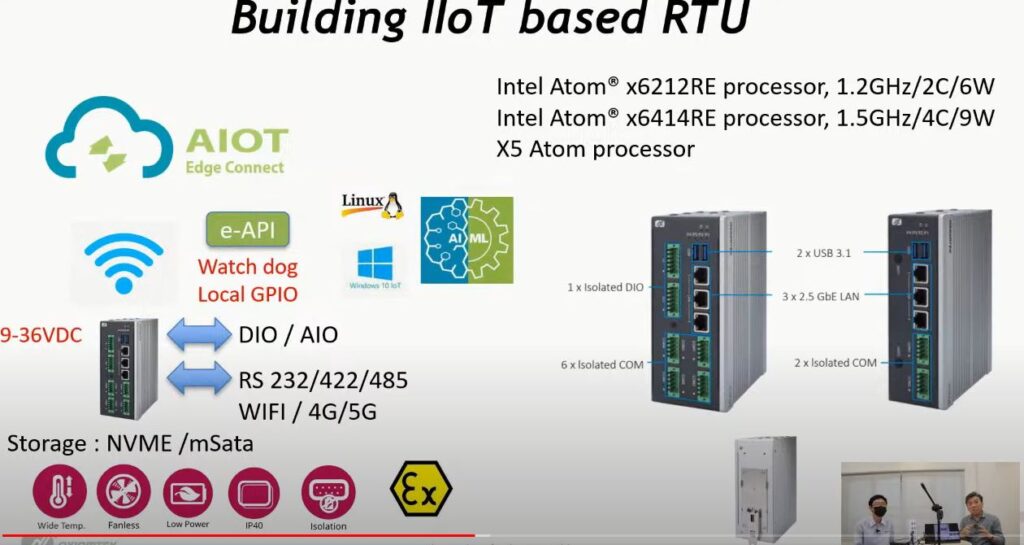

During the live session, Mr. CC Lee talk about the building block of developing the Remote Terminal units. The system components in term of hard and software necessary in the building of RTU was shared. One of the Axiomtek ICO platform was selected as a development platform of the RTU because, it has almost all features required by the RTU.

A Remote Terminal Unit (RTU) is a specialized device used in industrial control systems to monitor and manage remote equipment. It plays a crucial role in supervisory control and data acquisition (SCADA) systems, which are used in various industries such as manufacturing, energy, water treatment, and more.

Key features of an RTU include:

1. Remote Monitoring: RTUs are placed in remote locations to monitor and collect data from sensors and devices. These sensors could measure parameters like temperature, pressure, flow rates, voltage, or other relevant data depending on the application.

2. Data Acquisition: RTUs are equipped with input channels to collect analog and digital data from field devices. They convert this data into a digital format for transmission and processing.

3. Control Functions: In addition to monitoring, some RTUs also have control capabilities. They can send commands to remote devices, such as turning equipment on or off, adjusting settings, or executing specific actions based on the data they receive.

4. Communication: RTUs communicate with a central control system or a master station, usually located at a central facility. Common communication protocols include Modbus, DNP3 (Distributed Network Protocol), and others, depending on the industry standards and requirements.

5. Real-time Operation: RTUs are designed to operate in real-time, ensuring timely and accurate data acquisition and control.

6. Reliability and Environmental Resistance: Since RTUs are often deployed in harsh environments, they are designed to be robust and resistant to environmental factors such as extreme temperatures, humidity, and vibrations.

RTUs are a crucial component in the automation and control of processes in industries where remote monitoring and control are essential. They enable efficient management of distributed systems by providing a link between field devices and the central control system, allowing operators to make informed decisions and respond to changes in the environment or process.

As you can see, the RTU still stay a valid and important equipment in the process control especially at the remote area. In the sembang AIoT live session, we shared the building block of RTU, How Axiomtek’s ICO hardware+ IIoT software tools can be used to build a reliable RTU system that serve the industry.

Extracting data from a process plant poses significant challenges. The process involves substantial efforts, including the addition of extra components, sensor readjustments, configuration changes, and rewiring accompanied by commissioning tests. This not only incurs considerable work and costs but also results in substantial downtime.

In response to these challenges, we showcased a non-intrusive data extraction demonstration. This innovative approach involves extracting data from process displays without the need for additional hardware adjustments. The extracted data is seamlessly shared through a SCADA interface, providing real-time visibility on a Ruggedized tablet.

Subscribe and watch us live in the next coming session on ” JOM ! Let’s sembang AIOT” with the link below:-

https://www.youtube.com/watch?v=fK-coJE84z8