Overall Equipment Effectiveness (OEE)tracking via AIoT Technology

Overall Equipment Effectiveness (OEE) tracking is a well-established methodology for monitoring production equipment and processes, renowned for its effectiveness. By harnessing the power of Industrial IoT and AI technology, OEE tracking undergoes digital transformation to align with the demands of Industry 4.0, prioritizing connectivity and data transparency. This evolution enables the optimization of production and enhances efficiency by providing real-time insights and actionable data for informed decision-making.

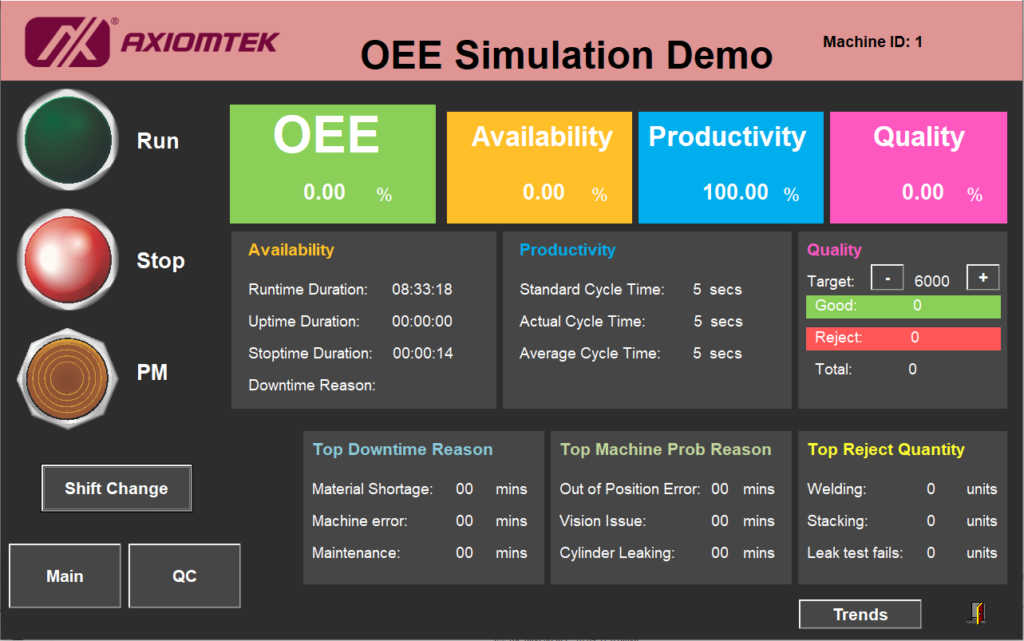

The Overall Equipment Effectiveness (OEE) index is determined by three primary data sources: Availability, Performance, and Quality. Leveraging IoT devices and tools enables the extraction of data from machines and processes, which is then utilized in calculating the OEE index using a specified formula, resulting in real-time online data generation.

Analyzing the OEE index provides insights into the effectiveness and efficiency of your processes. IoT devices and tools facilitate access to this data, connecting you to designated servers or platforms. Visualization capabilities are available both locally and via Cloud services.

AIoTmission’s AIoT OEE Training offers practical instruction, imparting a comprehensive understanding of IoT and AI’s role in developing an OEE Tracking system. Upon completion, participants gain the skills to implement these concepts effectively in real-world scenarios.me insights and actionable data for informed decision-making.

AIoTmission’s AIoT OEE Connect solutions offer both the learn and implement concept that emphasis on both integration and Training with practical instruction, imparting a comprehensive understanding of IoT and AI’s role in developing an OEE Tracking system. Upon completion, participants gain the skills to implement these concepts effectively in real-world scenarios.me insights and actionable data for informed decision-making.

There are 4 main key skill sets in the training:-

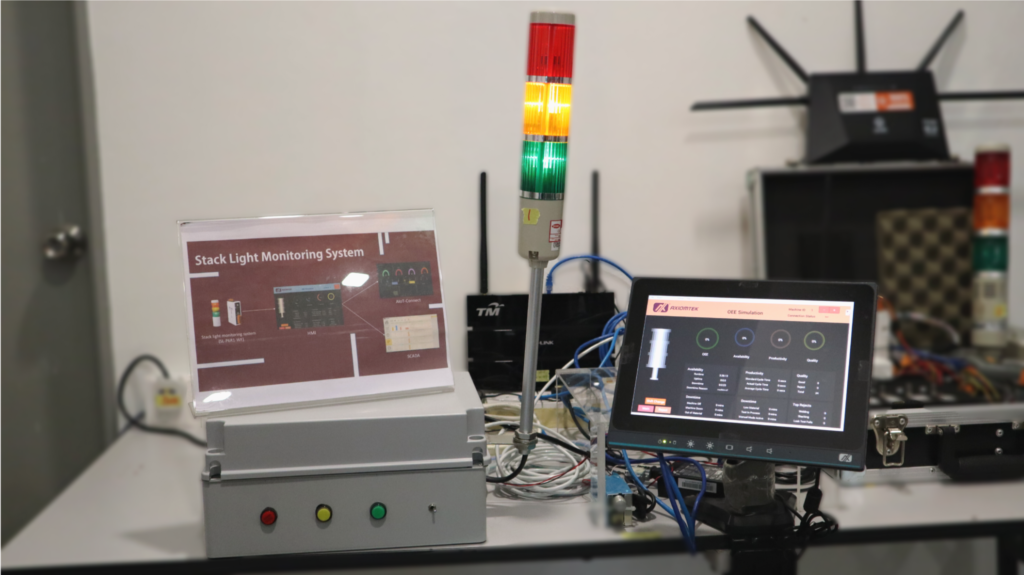

- IoT connectivity from sensors to the system

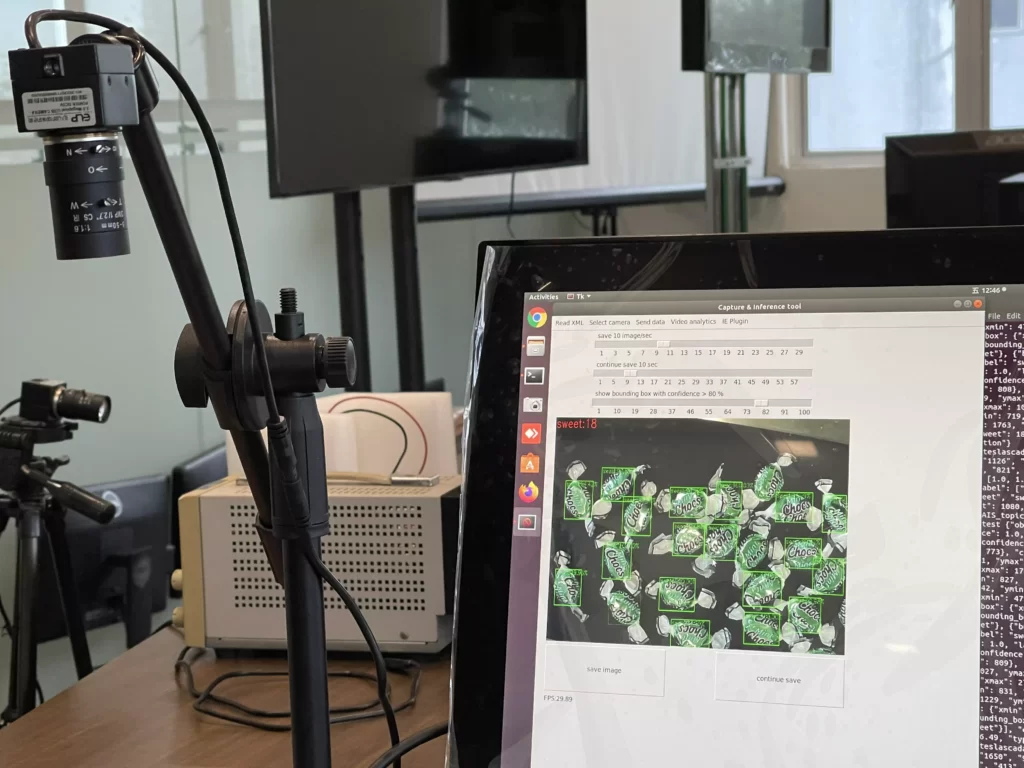

- AI application on Quality factors

- Data integration to databases and related production system.

- Data manipulation and visualization at local SCADA and Cloud.

AI Vision Deep learning Data Extractor setup

IIoT OEE Tracking Data Extractor setup

OEE Local Dashboard and cloud Dashboard