OEE Tracking Training with AI and IoT

Overall Equipment Effectiveness tracking is one of the most classical and proven methodologies of tracking production equipment and processes. With the help of Industrial IoT and AI technology, it can be digitally transformed to meet the requirement of Industry 4.0 where connectivity and data transparency is of main concern.

RiSE4WRD for Industry4WRD

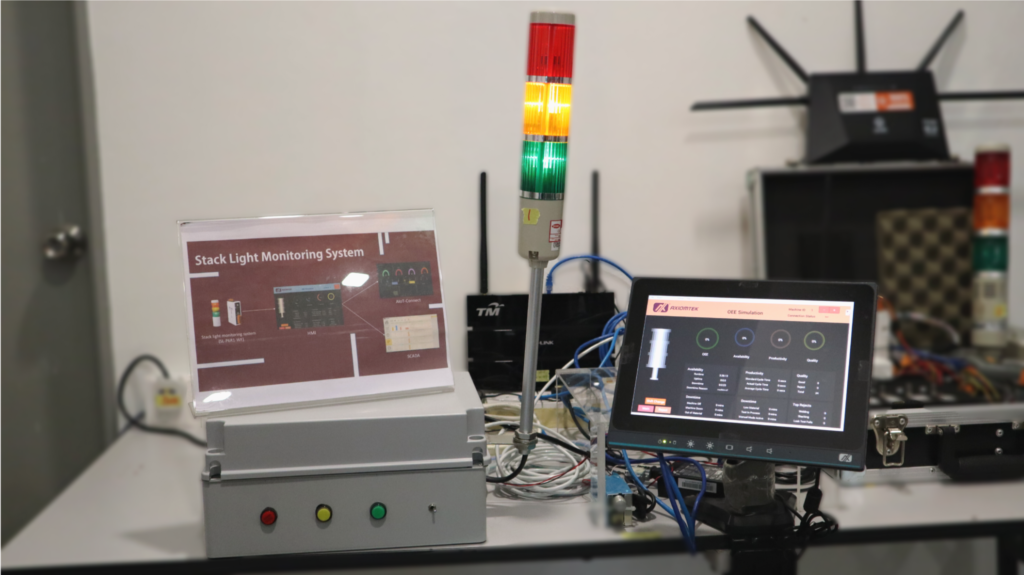

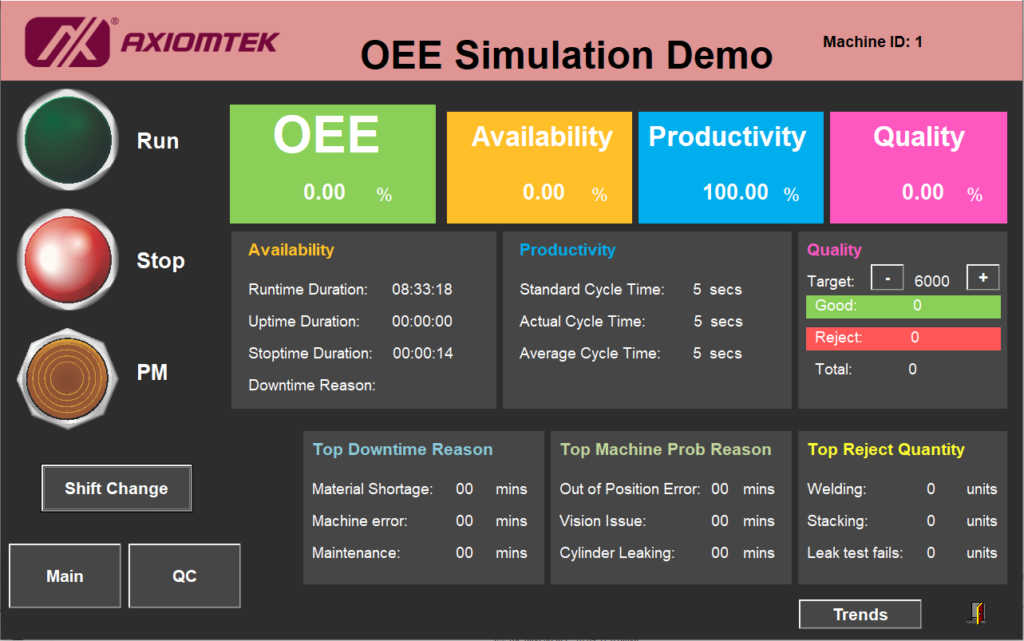

There are 3 main source of data that dictate the OEE index, Availability, Performance and Quality. By using the Iot devices and tool, data can be tapped from the machines and processes. Those data can then be calculated based on the formula in order to produce the online data of OEE index.

By looking at the OEE index, you will know how effective or how efficient your process is running. IoT devices and tools allowed you to make this available and connect to the wanted servers or platform. The visualization is make possible at the local site as well as Cloud.

AIoTmission AIoT OEE Training provides you a very practical training outcome where after the training, you should be able to know the overall concept of IoT and AI in the application of making up the OEE Tracking system and you should be able to put that into the implementation of the system.

There are 4 main key skill sets in the training:-

- IoT connectivity from sensors to the system

- AI application on Quality factors

- Data integration to databases and related production system.

- Data manipulation and visualization at local SCADA and Cloud.