6 key losses -The start up Defects

Understanding Start-Up Rejects in OEE:

A Hidden Quality Drain

What Are Start-Up Rejects?

Why Start-Up Rejects Matter

Detecting and Tracking Start-Up Rejects

-

Time-based tagging: Mark the first X minutes or Y units after start-up as “start-up phase.”

-

Sensor-triggered events: Use PLC signals or IoT device triggers to identify exact machine start points.

-

Manual entry: Operators log the first-good part or timestamp, though this is more error-prone.

Analyzing Root Causes of Start-Up Rejects

-

Incorrect parameter presets

-

Residual material contamination

-

Mechanical drift or wear

-

Improper tool alignment

-

Inadequate pre-startup checks

Enhancing Start-Up Quality with AI and Analytics

-

Predict when a machine is ready for optimal output

-

Trigger alerts if parameter drift is detected

-

Adjust warm-up profiles dynamically

-

Correlate reject types with specific operational anomalies

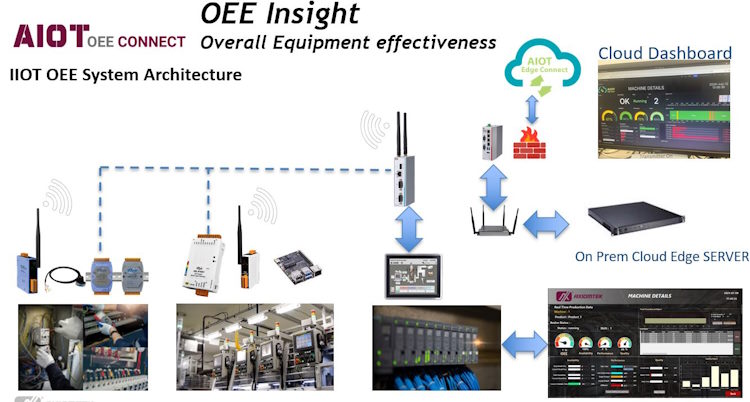

AIoT OEE Insight Connect is a groundbreaking, next-generation solution designed to deliver deep, real-time visibility into manufacturing performance. More than just an OEE (Overall Equipment Effectiveness) tracker, it offers a comprehensive and intelligent approach to uncovering the true drivers behind production efficiency — empowering smarter, faster decisions.

At its core, AIoT OEE Insight Connect excels in high-fidelity data acquisition, capturing critical information from:

-

Sensors and machines,

-

Controllers and PLCs,

-

Operator and human inputs.

This multi-layered data integration ensures a true 360° view of what impacts OEE, drilling down to the root causes that traditional systems often miss.

Hybrid-Cloud Flexibility: Modern, Secure, and Scalable

Harnessing the latest advances in cloud technology, AIoT OEE Insight Connect seamlessly streams all operational data to a secure, intuitive cloud dashboard.

At the same time, it gives manufacturers the freedom and flexibility to deploy the system fully within their on-premises infrastructure if preferred — maintaining control, security, and customization according to operational needs.

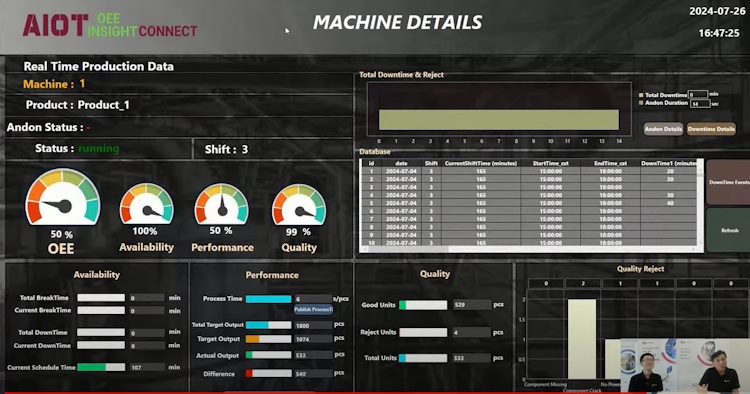

Actionable Intelligence with Generative AI

Where this solution truly stands apart is in its analytical intelligence:

-

Advanced reporting and analytics uncover patterns, bottlenecks, and optimization opportunities.

-

Generative AI integration goes a step further, automatically generating actionable recommendations and task lists designed to continuously enhance process performance.

By bridging real-time shop floor insights with AI-driven action plans, AIoT OEE Insight Connect ensures that continuous improvement becomes an embedded, automated process — not just an aspiration.

Key Benefits at a Glance:

-

Comprehensive OEE measurement and deep root-cause insights

-

Real-time, flexible access via cloud or on-premise deployment

AI-powered action plans for continuous process optimization

-

Seamless integration with existing industrial systems and infrastructures

AIoT OEE Insight Connect is not just a tool — it’s your partner in building a more efficient, agile, and intelligent manufacturing future.