OEE 6 Big Losses – The production Defects

The Power of OEE The beauty of OEE (Overall Equipment Effectiveness) lies in its comprehensive nature—it encapsulates all the essential components that define a meaningful key performance indicator (KPI) in manufacturing operations.Among the three core components of OEE—Availability, Performance, and Quality—Quality plays a critical role. Without producing a high number of good-quality units, speed and efficiency become irrelevant. No matter how fast or uninterrupted your production is, if the output is flawed, it diminishes the overall value.

The beauty of OEE (Overall Equipment Effectiveness) lies in its comprehensive nature—it encapsulates all the essential components that define a meaningful key performance indicator (KPI) in manufacturing operations.Among the three core components of OEE—Availability, Performance, and Quality—Quality plays a critical role. Without producing a high number of good-quality units, speed and efficiency become irrelevant. No matter how fast or uninterrupted your production is, if the output is flawed, it diminishes the overall value.One of the “Six Big Losses” tracked in OEE is Production Rejects. This metric serves as a vital indicator of whether upstream processes are performing well enough to produce acceptable output. Identifying product rejects is relatively straightforward, typically done via visual inspection or measurement/testing methods. If a product fails to meet the defined quality standards, it’s classified as a reject.The Quality component of OEE is calculated as: Quality (%) = (Good Units / Total Units Produced) × 100%This metric is effectively the yield rate that many manufacturers rely on. The ideal Quality score is 100%, indicating zero defects. However, high reject rates can significantly reduce the overall OEE score and signal underlying issues.Delving into production rejects provides insights into defect types and root causes. A commonly used tool by quality teams is the Pareto Chart, based on the 80/20 rule—where roughly 80% of defects stem from 20% of the causes. By identifying the most frequent defect types, quality teams can take targeted corrective actions to improve output quality.

To support this, standard IoT tools can be used to track defect data, whether through manual input (e.g., tablets or HMI panels) or automated systems. For advanced auto-tracking, computer vision systems—ranging from rule-based to machine learning and deep learning models—can detect and classify defects in real time.

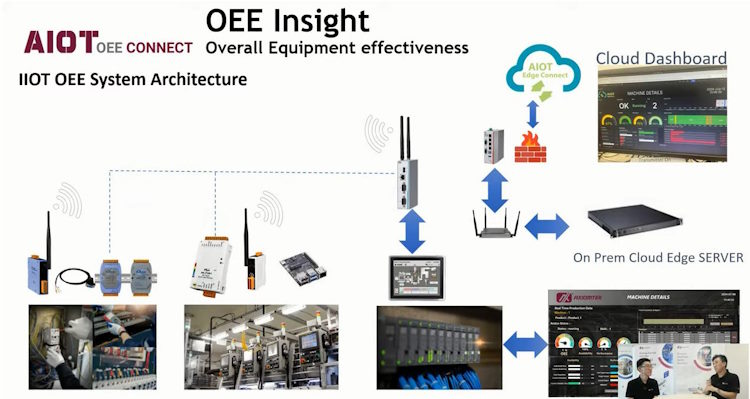

A centralized on-premise OEE server, such as one built with AdisRa SmartView, can aggregate data from manual entries or automatically from IIoT gateways like Axiomtek, edge HMIs, or edge AI systems. This creates a complete and continuous data feedback loop.

With the growing availability of data analytics tools, Quality Assurance can be further enhanced by feeding captured data into a larger historical database. Using statistical AI models—such as regression analysis, Random Forest, or Support Vector Machines—organizations can discover correlations between defects and process parameters. This enables predictive and data-driven corrective actions, ultimately optimizing production outcomes.

AIoTmission Sdn Bhd a Tech Startup, established in 2022 as a subsidiary of Axiomtek (M) Sdn Bhd, is a leading provider of technological training and consultancy services specializing in Artificial Intelligence (AI) and Industrial Internet of Things (IIoT) solutions. Our mission is to drive the Fourth Industrial Revolution (IR4.0) and facilitate digital transformation across Southeast Asia, including Malaysia, Singapore, Brunei, Indonesia, the Philippines, Thailand, Vietnam, Myanmar, Cambodia, and Laos.

At AIoTmission, we are dedicated to advancing research and development in AI and IIoT technologies, with a focus on industrial applications such as sensors, gateways, wireless communications, machine learning, AI deep learning, and Big Data cloud solutions. Through collaboration with our valued clients and partners, we deliver innovative solutions tailored to industry needs, enhancing technological capabilities and operational efficiency.