Highlights from the July 5th, 2024 Live Session: Integrating MES with Computer Vision AI

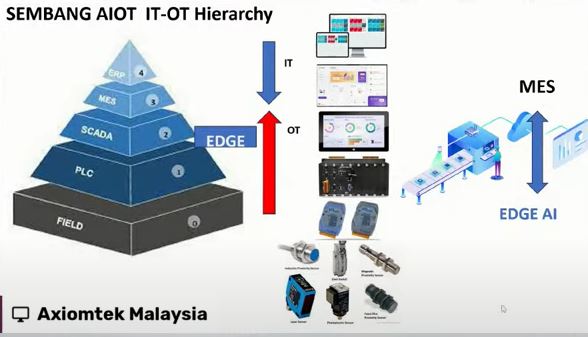

During our live session on July 5th, 2024, we explored the critical integration of Manufacturing Execution Systems (MES) with computer vision AI. We highlighted AIOT AIS CONNECT as a leading computer vision solution, known for its flexibility in data exchange with external software through open protocols like Web API and MQTT.

In the rapidly evolving landscape of manufacturing, the integration of advanced technologies is reshaping the industry. At the forefront of this transformation is the Manufacturing Execution System (MES), a pivotal tool that streamlines production processes and enhances efficiency. Coupled with AI-driven computer vision, MES is ushering in a new era of smart factories. Let’s delve into the key functions of MES and explore why computer vision AI is so crucial in this context.

Key Functions of MES: The Backbone of Modern Manufacturing

Production Scheduling:

MES excels in planning and scheduling production processes, ensuring optimal use of resources and timely product delivery. This minimizes downtime and enhances overall efficiency.

Resource Management:

Efficiently managing machinery, labor, and materials, MES ensures resources are utilized to their fullest potential, reducing waste and operational costs.

Work Order Management:

From creation to completion, MES tracks and manages work orders, ensuring production processes are followed meticulously and issues are swiftly addressed.

Quality Management:

MES monitors and controls product quality during manufacturing, maintaining high standards and reducing defects, ultimately improving customer satisfaction.

Data Collection and Analysis:

By collecting data at various production stages, MES provides valuable insights into performance, enabling data-driven decision-making.

Performance Analysis:

Analyzing key performance indicators like production yield and equipment efficiency, MES identifies areas for improvement, optimizing production processes.

Traceability:

MES tracks the entire product lifecycle, ensuring compliance with regulations and facilitating quick responses to product recalls.

Inventory Management:

Managing inventory levels of raw materials, work-in-progress, and finished goods, MES helps reduce costs and prevent stockouts or overstock situations.

The Power of Computer Vision AI in Smart Factories

As MES continues to evolve, the integration of computer vision AI is proving to be a game-changer for smart factories. Here’s why:

Enhanced Quality Control:

AI-powered cameras inspect products in real-time for defects, ensuring higher quality and reducing defect rates, which leads to improved customer satisfaction.

Automated Inspection:

Automating the inspection process eliminates manual checks, speeding up production and reducing human error, while allowing continuous monitoring.

Predictive Maintenance:

Analyzing visual data from equipment, AI predicts potential failures before they occur, minimizing unexpected downtime and extending machinery lifespan.

Real-time Monitoring:

Providing real-time production process monitoring through visual data, AI enables immediate detection and correction of issues, ensuring smooth operations.

Improved Safety:

AI monitors factory environments and worker activities for safety compliance, reducing accident risks and ensuring a safer workplace.

Process Optimization:

Analyzing visual data, AI identifies bottlenecks and optimizes production processes, significantly improving efficiency.

Traceability and Documentation:

Offering visual documentation of the production process, AI ensures compliance with industry standards and facilitates product recalls when necessary.

Enhanced Decision Making:

AI provides detailed visual data and analytics, supporting informed decision-making based on accurate, real-time information.

Conclusion

The synergy between MES and computer vision AI is transforming manufacturing into a more efficient, high-quality, and safe industry. As smart factories become the norm, these technologies are not just enhancing production performance but also setting new standards for the future of manufacturing. The combination of MES and AI-driven computer vision is truly revolutionizing the way we produce and deliver goods, heralding a new era of innovation and productivity.

Announcing the Industrial AIoT Master Class

We are excited to introduce the Industrial AIoT Master Class, a three-day practical training program focused on Industrial IoT and AI applications. This comprehensive program offers hands-on training and is designed for individuals with no prior programming experience. It is ideal for fresh graduates and working professionals who want to embrace digital transformation and gain advanced knowledge and skills in IoT and AI.

Who Should Attend?

Fresh Graduates: Start your career with cutting-edge knowledge and skills in IoT and AI.

Working Adults: Enhance your career prospects by tapping into the digital transformation wave and acquiring high-tech expertise.

Key Features

Hands-on Training: Practical exercises and real-world applications.

No Programming Background Required: Designed for accessibility to all participants.

Upcoming Webinar

Next week, we are hosting a webinar to delve deeper into the applications of AIoT. Join us for insightful discussions and detailed application sharing on this exciting subject.

Don’t miss this opportunity to elevate your expertise and stay ahead in the evolving industrial landscape.

AIOT Master Class Webinar preview :

Scan the QR code to find out more information.

Demonstration of the object Detection AI.

Find out more from our Youtube channel :

https://youtube.com/live/f0fLYNLPC1k