Industrial transformation with AIoT

During our live session on March 22nd, 2024, hosted by AioTmission, the focus was on the potential commoditization or monetization of datasets. As data increasingly drives decision-making processes to enhance efficiency and predictability with AI, standardizing the dataspace becomes imperative.

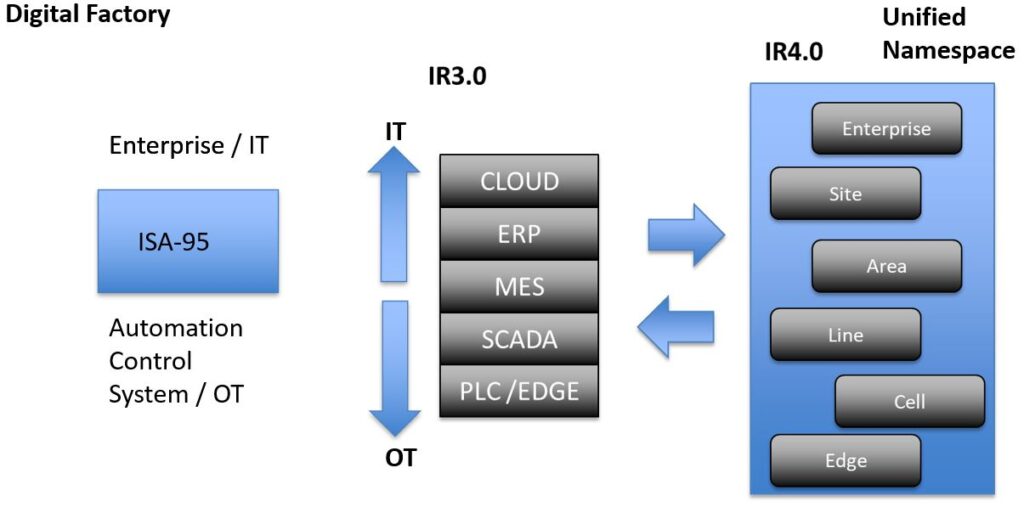

Transitioning from Industry 3.0 to 4.0 necessitates a standardized framework to facilitate a smooth transformation, ensuring manageability throughout the process.

There is this standard framework in the transformation, the ISA-95.

ISA-95, or the International Society of Automation Standard 95, is a widely recognized standard in the realm of manufacturing and automation. It provides guidelines for integrating enterprise and control systems in industrial environments. Originally developed in the 1990s, ISA-95 has been instrumental in defining the interface between enterprise resource planning (ERP) systems and manufacturing execution systems (MES) or even SCADA ( supervisory control and Data acquisition).

In the context of the transition from Industry 3.0 to Industry 4.0, ISA-95 plays a crucial role in facilitating interoperability and data exchange between different systems and layers within a digital factory including the top layer of Cloud integration.. Here’s how it helps in this transformation:

Interoperability: ISA-95 defines standardized interfaces and communication protocols, enabling seamless integration between various components of the manufacturing process. This interoperability is essential for transitioning from siloed systems of Industry 3.0 to interconnected, data-driven systems of Industry 4.0.

Data Integration: By providing a common framework for data exchange, ISA-95 allows for the integration of data from disparate sources across the manufacturing enterprise. This integrated data is foundational for implementing advanced analytics, machine learning, and other Industry 4.0 technologies.

Visibility and Control: ISA-95 facilitates real-time visibility into manufacturing operations by standardizing the exchange of production data between different levels of the manufacturing hierarchy, such as the shop floor, supervisory control, and enterprise levels. This visibility is essential for implementing agile and responsive manufacturing processes characteristic of Industry 4.0.

Scalability: As manufacturing systems evolve from traditional hierarchical architectures to more distributed and modular architectures in Industry 4.0, ISA-95 provides a scalable framework for managing the complexity of interconnected systems. This scalability ensures that digital factories can adapt and grow in line with evolving business needs and technological advancements.

In summary, ISA-95 serves as a foundational standard for enabling the seamless integration, interoperability, and data exchange necessary for the transition from Industry 3.0 to Industry 4.0 in digital factories. By adopting ISA-95 guidelines, manufacturers can streamline their operations, improve efficiency, and unlock the full potential of Industry 4.0 technologies.

How ISA-95 frame helps in digital transformation

There is this UNS ( Unified NameSpace) in the context of industrial transformation.

A unified namespace refers to a single, standardized system for naming and organizing data across an organization or within an industrial ecosystem. In the context of industrial transformation, particularly in the transition to Industry 4.0, a unified namespace plays a crucial role in enabling seamless data integration, interoperability, and collaboration among various systems, devices, and stakeholders. Here’s how:

Data Integration: Industrial environments typically consist of diverse systems, equipment, and sensors from different vendors, each with its own data formats and naming conventions. A unified namespace provides a standardized approach to representing and organizing data, making it easier to integrate information from disparate sources into a cohesive digital infrastructure.

Interoperability: With a unified namespace, different components within the industrial ecosystem can communicate and exchange data more effectively. Standardized naming conventions and data formats ensure that systems can understand and interpret information correctly, facilitating interoperability between devices, machines, and software applications.

Collaboration: In modern industrial settings, collaboration between different departments, teams, and even organizations is essential for driving innovation and efficiency. A unified namespace provides a common language for describing and accessing data, fostering collaboration among stakeholders across the entire value chain.

Scalability: As industrial systems grow and evolve, a unified namespace provides a scalable foundation for managing the increasing volume and complexity of data. By establishing standardized data structures and naming conventions upfront, organizations can adapt more easily to changing requirements and technologies without sacrificing interoperability or data consistency.

Data Analytics and Insights: A unified namespace simplifies data management and analysis, enabling organizations to derive valuable insights and intelligence from their industrial data. By establishing a consistent framework for organizing and accessing data, organizations can more effectively apply advanced analytics, machine learning, and other data-driven technologies to optimize operations, improve decision-making, and drive continuous improvement.

Overall, a unified namespace is a fundamental enabler of industrial transformation, providing the infrastructure needed to integrate, standardize, and leverage data effectively across the entire industrial ecosystem. By adopting a unified approach to data naming and organization, organizations can unlock the full potential of Industry 4.0 technologies and realize the benefits of increased efficiency, agility, and innovation.

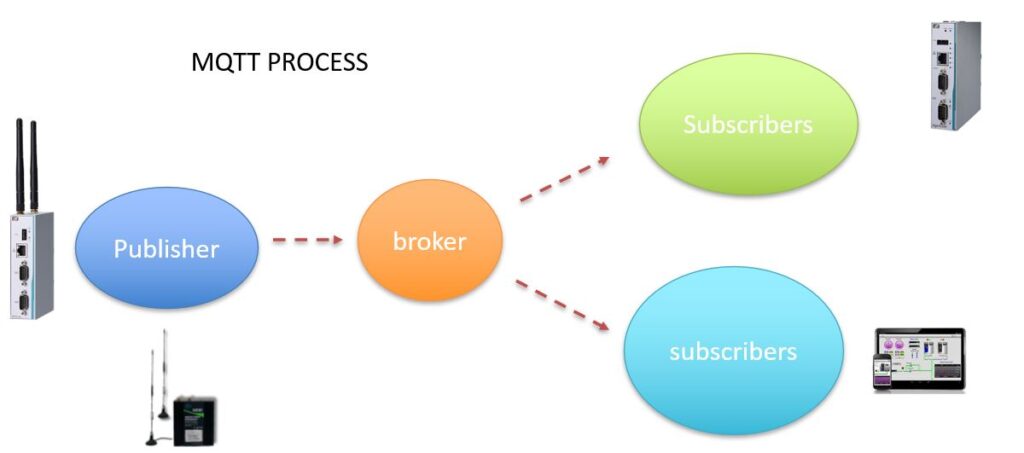

MQTT (Message Queuing Telemetry Transport) is a lightweight messaging protocol designed for the efficient exchange of data between devices in constrained environments, such as those with low bandwidth, high latency, or limited processing power. Here’s how MQTT works:

Client-Server Architecture: MQTT follows a client-server architecture where clients (devices or applications) connect to a central server, known as the MQTT broker. The broker is responsible for routing messages between clients.

Publish-Subscribe Model: MQTT uses a publish-subscribe messaging pattern. Clients can publish messages to specific topics, and other clients can subscribe to these topics to receive messages. This decoupling of senders and receivers allows for flexible and efficient communication between devices.

Topics: Topics are hierarchical strings used to categorize messages. They are represented as a series of segments separated by forward slashes (/), similar to a file path. Clients can publish messages to specific topics or subscribe to topics to receive messages. For example, a topic could be sensors/temperature to represent temperature sensor data.

Quality of Service (QoS): MQTT supports different levels of message delivery assurance through its Quality of Service levels:

QoS 0 (At most once): Messages are delivered at most once, with no guarantee of delivery.

QoS 1 (At least once): Messages are guaranteed to be delivered at least once, but duplicates may occur.

QoS 2 (Exactly once): Messages are guaranteed to be delivered exactly once, but this level of assurance comes with increased overhead.

Connection Establishment: Clients establish a connection with the MQTT broker using TCP/IP or other transport protocols. The client can specify its client identifier and may also provide authentication credentials if required by the broker.

Keep-Alive Mechanism: Once connected, clients maintain their connection to the broker using a keep-alive mechanism. Clients periodically send PINGREQ messages to the broker, and the broker responds with PINGRESP messages to indicate that the connection is still active.

Message Transmission: When a client publishes a message to a topic, it sends the message to the broker, which then forwards the message to all clients subscribed to that topic. The broker may also retain messages for clients that are not currently connected, depending on the configuration.

Message Retention: MQTT brokers can be configured to retain the last message published to a topic. This allows new subscribers to immediately receive the last known value when they subscribe to a topic.

Security: MQTT supports various security features, including authentication, access control lists (ACLs), and encryption (TLS/SSL), to ensure the confidentiality, integrity, and authenticity of message transmission.

Overall, MQTT’s lightweight design, efficient publish-subscribe model, and support for various quality of service levels make it well-suited for a wide range of IoT and M2M (machine-to-machine) communication scenarios.

To check out how IIoT sensor integration to the Cloud, click here.

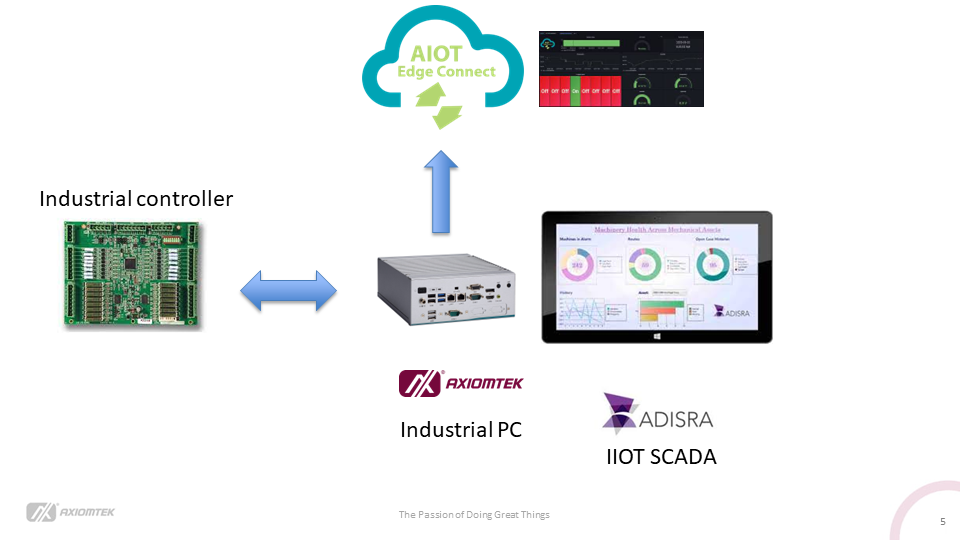

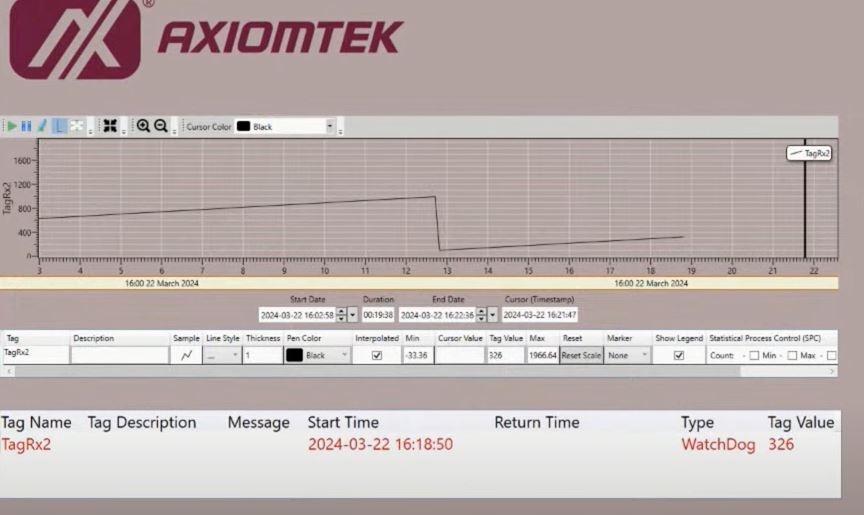

In the session, we demonstrate the proprietory serial data interface to SCADA – The Adisra SCADA – an easier tool for proprietory data integration

Demonstration continued with the integration from SCADA to AIoT edge Connect Cloud platform.

Watch the demonstration session only at the youtube.