Navigating Evolution from Industrial Revolution 4.0 and 5.0

During the recent “Let’s Sembang AIoT Session,” we delved deeper into the progression of the industrial revolution, revisiting key points and exploring their connection to transformative technologies such as AI and IoT. Our discussion shed light on the intricate relationship between these advancements and the evolution of industry.

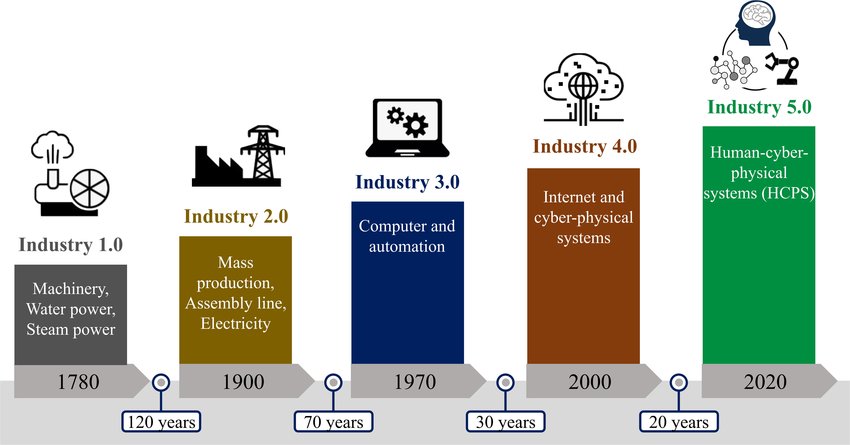

Industrial Revolution 1.0 (18th to 19th centuries):

Introduction of Mechanization: This revolution was marked by the transition from agrarian economies to industrial ones, primarily powered by the invention of the steam engine.

Early mechanization laid the foundation for modern manufacturing processes, focusing on efficiency through machinery and standardization.

Industrial Revolution 2.0 (Late 19th to early 20th centuries):

Mass Production: This era saw the rise of assembly lines and interchangeable parts, notably spearheaded by innovations like the electric motor and the assembly line.

Standardization and mass production became central, emphasizing economies of scale and process optimization. Introduction of early automation concepts streamlined production.

Industrial Revolution 3.0 (Late 20th century):

Automation and Electronics: The advent of computers and automation technologies revolutionized manufacturing, enabling more precise control and customization.

Automation expanded significantly, integrating computer-controlled systems for inventory management, production scheduling, and quality control. Emphasis on data collection and analysis for process optimization.

Industrial Revolution 4.0 (21st century):

Digitalization and Interconnectivity: Industry 4.0 is characterized by the fusion of digital technologies with traditional manufacturing processes, leveraging concepts like IoT, AI, and big data.

Smart factories emerged, where cyber-physical systems monitor processes in real-time, enabling predictive maintenance, agile production, and personalized manufacturing. Integration of IoT devices and AI algorithms optimize production workflows and resource utilization.

Industry 5.0 (Emerging):

Human-Centric Automation: Industry 5.0 seeks to reconcile automation with human labor, emphasizing collaboration between humans and machines.

This era focuses on integrating advanced robotics and AI with human expertise, fostering a symbiotic relationship where machines augment human capabilities rather than replacing them entirely. Adaptive manufacturing systems respond dynamically to human input and evolving market demands.

In practical terms, smart manufacturing principles across these revolutions involve leveraging technology to enhance efficiency, quality, and flexibility in production processes. This includes deploying sensors for real-time monitoring, utilizing data analytics for predictive maintenance and quality assurance, implementing robotics and automation for repetitive tasks, and integrating AI for decision support and optimization. Ultimately, the aim is to create agile, adaptive manufacturing systems that can respond effectively to changing market dynamics while maximizing productivity and resource efficiency.

Axiomtek industrial IoT gateway were introduced in the application of AIoT OEE Connect where a standard node red open source development tool can be used in this ICO120, one of the IIOT edge gateway that is capable of handling most data collection requirement in manufacturing environment.

To Watch our session on some discussion topic relate to the industrial revolution, click the link below:-