Deploying AI in Smart Manufacturing

AIoTmission live session on 8th of March 2024 discussed about the the fundamental of AI and the applications in IR4.0 and smart manufacturing.

The deployment of Artificial Intelligence (AI) in smart manufacturing offers numerous possibilities to enhance efficiency, productivity, and overall operational performance. Here are several ways AI can be deployed in smart manufacturing:

Predictive Maintenance:

AI algorithms can analyze data from sensors and equipment to predict when machinery is likely to fail. This enables proactive maintenance, minimizing downtime and reducing the likelihood of unexpected breakdowns.

Quality Control and Inspection:

Computer vision powered by AI can be utilized for automated visual inspections on the production line. This ensures high-quality products by detecting defects, variations, or deviations from standards in real-time.

Production Planning and Optimization:

AI can optimize production planning by analyzing historical data, market demand, and resource availability. This helps in creating efficient production schedules, reducing lead times, and maximizing resource utilization.

Supply Chain Management:

AI applications in supply chain management can predict demand, optimize inventory levels, and enhance logistics. This ensures a streamlined flow of materials, reduces stockouts, and minimizes excess inventory.

Energy Management:

AI-driven systems monitor and analyze energy consumption patterns in manufacturing processes. By providing insights into energy usage, AI helps in optimizing energy consumption, reducing costs, and supporting sustainability initiatives.

Process Optimization:

AI algorithms can continuously analyze and optimize manufacturing processes in real-time. This includes adjusting parameters for optimal efficiency, reducing waste, and improving overall process performance.

Human-Robot Collaboration:

AI facilitates collaborative robotics (cobots) that work alongside human operators. These robots can handle repetitive tasks, allowing human workers to focus on more complex and value-added activities.

Digital Twins:

AI is used to create digital twins of physical manufacturing systems. These virtual replicas simulate real-world processes, allowing for testing and optimization before implementing changes in the physical environment.

Fault Detection and Diagnostics:

AI systems can automatically detect faults or abnormalities in equipment and processes. Once anomalies are identified, AI can provide diagnostic information to help resolve issues promptly.

Customized Production:

AI enables mass customization by adjusting production processes to create customized products efficiently. This is achieved by analyzing customer preferences and adapting manufacturing lines accordingly.

Data Analytics for Decision-Making:

AI processes vast amounts of data generated in manufacturing to provide actionable insights. This supports data-driven decision-making at various levels of the organization, from the shop floor to strategic planning.

The deployment of AI in smart manufacturing contributes to creating agile, efficient, and adaptive production systems that can respond to dynamic market conditions and customer demands.

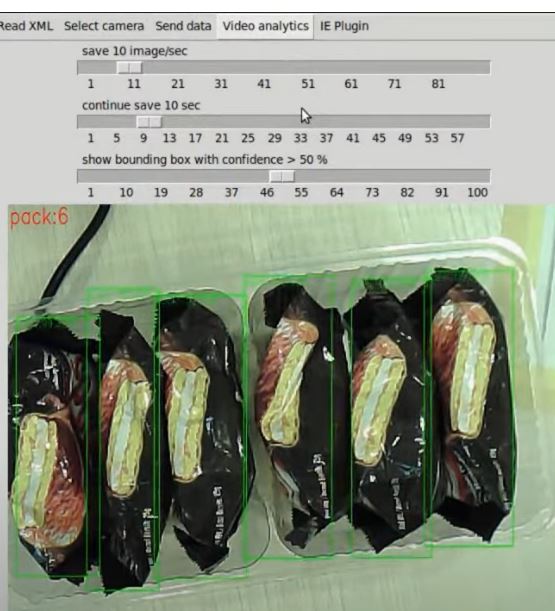

Axiomtek AI Suite is a deep learning development suite that gives an intuitive approach in the building of Vision AI model and applications in the manufacturing process. Man power Reduction, Quality Control and Wastage reduction are the aims in the deployment.

In Food and Beverage industry, there are many packaging processes that require visual inspection. AIS ( AI suite) is one of the tool that provides an end to end from deep learning to the inferencing with minimum coding. the picture on the right hand side, show the AI inferencing process on the AIS.

Beside AI, industrial IoT application in manufacturing is also one of the frequently deployment that works with AI.

To watch the live session click at the link below:-