AIoT sensors to Cloud & Data Analytic

In manufacturing, numerous processes necessitate controlled heating, underscoring the paramount importance of accurate temperature measurement. Processes such as metal forging, welding, boiling, pasteurization, drying, and many others demand meticulous temperature regulation to guarantee superior product quality.

What are the principal sensors utilized for temperature measurement? Furthermore, which IIoT devices facilitate the digitization of these readings for enhanced monitoring and control? Which tools offer optimal visualization coupled with robust data analytics at the cloud level? These critical topics were the focal points of our recent “Sembang AioT session.” This discussion aimed to shed light on essential temperature-measuring instruments and advanced IIoT devices, underlining their significance in ensuring precise temperature control and, consequently, contributing to the production of high-caliber products.

There are three types of temperature sensors that are widely used in industries.

1. Thermocouples (TCs):

Working Principle: Based on the Seebeck effect, where a voltage is produced when two different metals are joined together and the junction is heated.

Application: Used in various industrial applications due to their wide temperature range, ruggedness, and accuracy.

2. Resistance Temperature Detectors (RTDs):

Working Principle: RTDs work on the principle that the electrical resistance of a material (typically platinum) changes with temperature.

Application: Used in precision temperature measurement applications as they offer high accuracy and stability over a narrow temperature range.

3. Thermistors:

Working Principle: Thermistors are temperature-sensitive resistors whose resistance changes significantly with temperature. There are two types – NTC (negative temperature coefficient) thermistors and PTC (positive temperature coefficient) thermistors.

Application: Used for accurate temperature measurements in a limited temperature range.

Their applications are as follows:-

Thermocouples are suitable for measuring high temperatures and are used in various industrial applications, such as furnaces and processing plants. Wide temperature range -200 C to 1800 degree C.

RTDs offer high accuracy and stability for lower temperature measurements and are widely used in scientific and industrial settings. The range of the temperature is from -250 C to 1000 Degree C.

Thermistors are typically used in low to moderate temperature measurements, including climate control and medical devices. The temperature ranges from -55 C to 114 degree C

After having the right temperature sensors elements, next is to have a suitable IO module that allows you to do measurement. The picture beside this shows some Temperature module (Thermocouple input & RTD sernsor input module) that supports Modbus RTU or Modbus TCP that provide a interface on serial or Lan port to be connected to the Axiomtek IIoT edge gateway or the AEC310 4G router gateway .

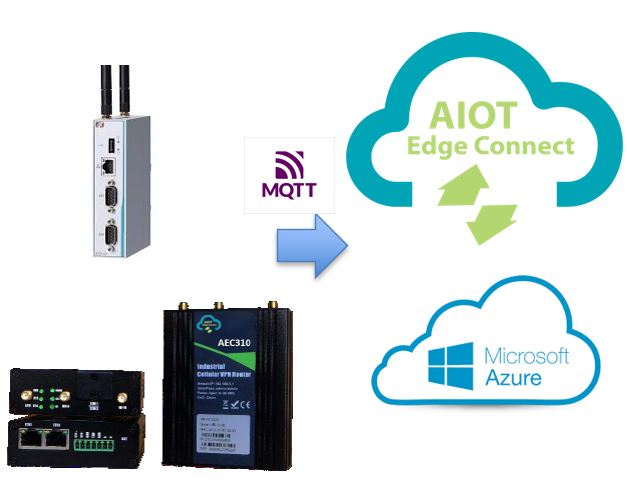

There are several way of how to treat the data collected. One of them is to allow the IIoT edge gateway or another 4G gateway to acquire from it, like what it is showed in picture at the right hand side

As for Cloud wise, AIoT Edge Connect cloud platform that is sitting on the Microsoft Azure can be used to receive all data collected and can then be shown on the Cloud Dashboard.

In this live session, Kien Leong delved into the requirements and standards for AI datasets used in training and deep learning.

The critical role of datasets was discussed, emphasizing not only their utility for AI training but also their essential function in testing and evaluating the accuracy of AI models. A suggested dataset distribution was presented, advocating for a 70-20-10 proportion to enhance practical AI deployment. This entails allocating 70% of the dataset for training, 20% for validation, and the remaining 10% for testing to ascertain model accuracy, a configuration applicable to most AI applications. Further discussion was centered around the different classes of datasets.

For a comprehensive insight into these crucial topics, you are encouraged to watch the live session. Ensure to subscribe to the channel using the link below to stay abreast with forthcoming intriguing discussions on AIoT.

Please watch this at the link below:-

https://youtube.com/live/ADSdC9QkT4s