Non-intrusive data extraction with AIoT

Non-intrusive data extraction refers to a method of collecting information from a system or process without physically disrupting or altering the operation of that system. In the context of industrial processes, such as manufacturing or automation, data extraction is essential for monitoring and optimizing performance. Traditional methods of data extraction often involve intrusive measures, such as installing additional sensors or modules with wiring, which can be time-consuming and may interrupt the normal functioning of the system.

In the non-intrusive approach, the data is collected without the need for physical interference or modifications to the existing infrastructure. Instead, visual data or images from the system’s indicators or displays are used. These visual inputs are then processed using artificial intelligence (AI) and other technologies to extract relevant information. This method eliminates the need for additional cabling, termination, or the installation of extra sensors.

Non-intrusive data extraction is often considered more cost-effective and efficient compared to intrusive methods, as it minimizes downtime and reduces the complexity associated with modifying existing systems. It is particularly relevant in the context of the Industrial Internet of Things (IIoT) and AIoT (Artificial Intelligence of Things) technologies, where data-driven insights are crucial for improving operational efficiency and decision-making

ebox100-312 a Fanless mini industrial PC system was introduced it can be used in some AI Edge applications it may involve” nonintrusive data extraction” for most of the processes that have a visual output

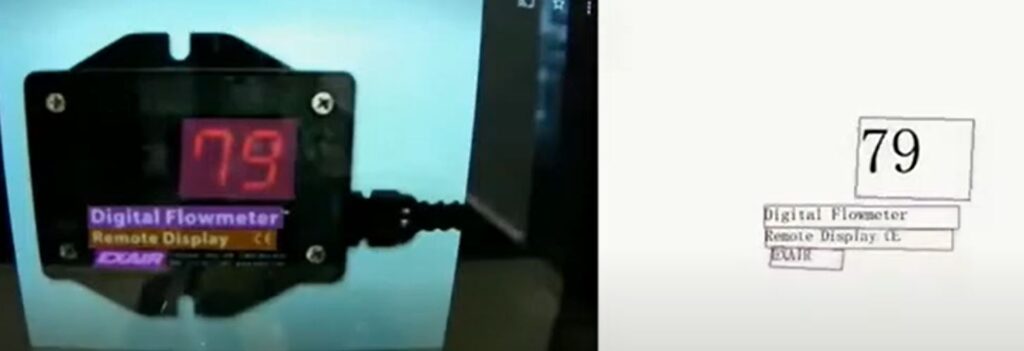

Flow meters or indicators having a 7 segment display allow Vision AI OCR to perform a non-intrusive reading via a Camera and data can be extracted effectively.

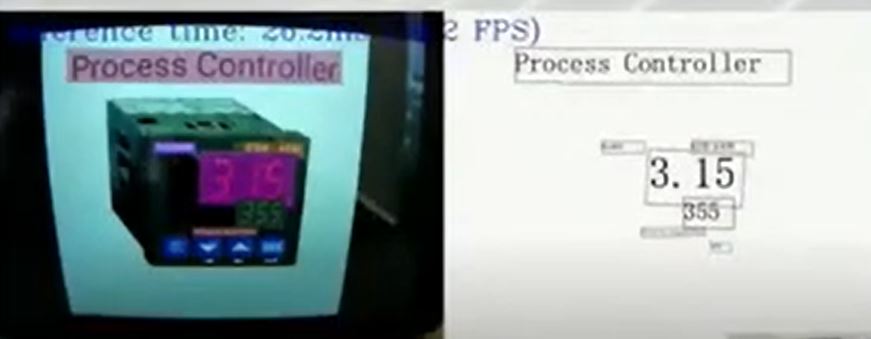

Process controller data exstraction with AIOTmission’s AIOT Non Intrusive Connect

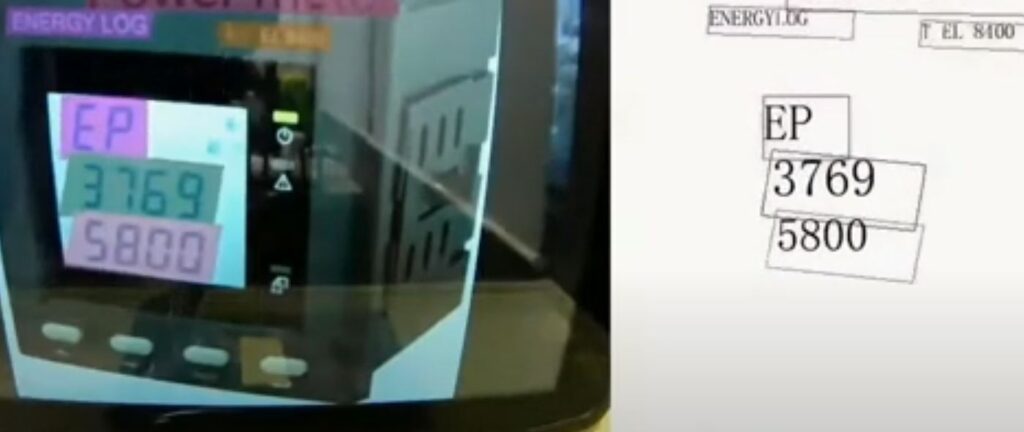

Energy meters at the shop floor or utility room with digital indicators allow AIOT Non-intrusive Connect’s solutions to extract data effectively and later on publish to AIOT EDGE CONNECT IOT Cloud platform.

Non-intrusive data extraction is often considered more cost-effective and efficient compared to intrusive methods, as it minimizes downtime and reduces the complexity associated with modifying existing systems. It is particularly relevant in the context of the Industrial Internet of Things (IIoT) and AIoT (Artificial Intelligence of Things) technologies, where data-driven insights are crucial for improving operational efficiency and decision-making

1. Reduced Downtime: Non-intrusive methods allow for data extraction without interrupting the normal operation of manufacturing processes. This helps reduce downtime, ensuring that production can continue without unnecessary halts.

2. Cost Savings: By eliminating the need for additional sensors, wiring, and complex installation processes, non-intrusive data extraction can lead to cost savings. There’s no expenditure on physical modifications or the purchase of extra hardware.

3. Enhanced Flexibility: Non-intrusive methods provide greater flexibility in data collection. Visual data or images can be captured from existing indicators or displays, making it easier to adapt to different manufacturing setups without the need for significant reconfiguration.

4. Real-time Monitoring: Non-intrusive data extraction often enables real-time monitoring of manufacturing processes. The use of AI and advanced analytics allows for immediate analysis and response to changing conditions, leading to improved efficiency and quality control.

5. Scalability: As manufacturing plants evolve, non-intrusive methods can be more easily scaled to accommodate changes in production requirements. This scalability is especially important in dynamic manufacturing environments.

6. Minimized Safety Risks: Intrusive methods, involving physical alterations to machinery, may pose safety risks. Non-intrusive data extraction minimizes these risks by avoiding the need for extensive physical interventions.

7. Integration with AI and IIoT: Non-intrusive data extraction aligns well with the broader trends of Artificial Intelligence (AI) and the Industrial Internet of Things (IIoT). The visual data captured can be analyzed using AI algorithms, providing valuable insights for optimizing processes and predicting maintenance needs.

8. Enhanced Data Accuracy: Non-intrusive methods may lead to enhanced data accuracy as they capture information directly from existing indicators. This can contribute to more reliable decision-making and better overall process control.

9. Adaptability to Legacy Systems: Manufacturing plants often have legacy systems in place. Non-intrusive data extraction allows for the integration of modern data collection techniques with older infrastructure, extending the lifespan and functionality of existing systems.

10. Compliance with Industry Standards: Non-intrusive methods may facilitate easier compliance with industry standards and regulations since they avoid physical alterations that could impact compliance.

In summary, non-intrusive data extraction in manufacturing plants opens up possibilities for improving efficiency, reducing costs, and facilitating the integration of advanced technologies for smarter, more adaptive production processes.

Watch our Youtube channel at the link below:-

https://youtube.com/live/8xaz9r4jl5c