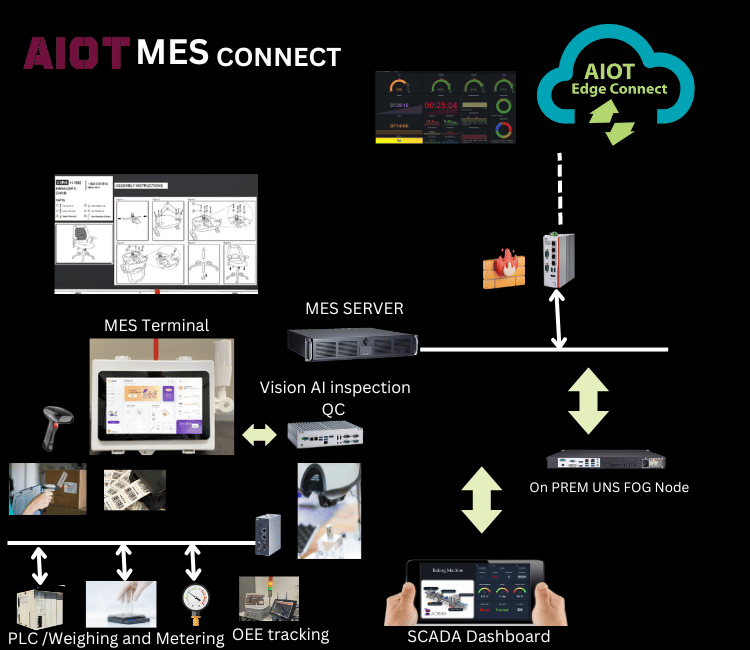

Welcome to AIOT MES CONNECT, a comprehensive manufacturing execution system designed to streamline operations, boost productivity, and ensure high product quality for small and medium-sized enterprises (SMEs). This robust solution integrates seamlessly with AIOT EDGE Connect Cloud and AIOT OEE Insight Connect for in-depth OEE tracking, equipping you with the tools necessary to excel in today’s competitive landscape.

Key Features of AIOT MES CONNECT

1. Production Management

AIOT MES CONNECT provides essential tools for effective production management, from planning to scheduling and optimization, ensuring efficient resource use and timely deliveries.

- Production Scheduling: Adapt production schedules in real-time to meet dynamic demand.

- Work Order Management: Automate and monitor work orders from inception to completion for efficient task execution.

- Resource Allocation: Allocate labor, machinery, and materials strategically to enhance productivity.

2. Inventory Management

Efficient inventory control is crucial for minimizing costs and preventing delays. AIOT MES CONNECT enables real-time tracking and management, ensuring essential materials are available as needed.

- Real-Time Materials Tracking: Track raw materials, work-in-progress (WIP), and finished goods continuously.

- Inventory Control: Maintain optimal stock levels, avoiding both shortages and surplus.

- Lot and Serial Number Tracking: Achieve full traceability across the supply chain for compliance and quality.

3. Quality Management

AIOT MES CONNECT integrates quality management tools to uphold rigorous quality standards, ensuring customer satisfaction and regulatory compliance.

- Quality Control: Conduct inspections and capture quality data at each stage of production in real-time.

- Non-Conformance Management: Log and manage any defects or deviations to sustain quality standards.

- Statistical Process Control (SPC): Employ statistical methods for continuous process control.

4. Production Tracking and Reporting

Gain actionable insights into production through real-time data capture, helping you make informed decisions and optimize operations effectively.

- Real-Time Data Collection: Gather data from machines and operators to monitor production in real-time.

- Performance Metrics: Measure KPIs such as yield, scrap rates, and machine uptime for comprehensive analysis.

- Reporting and Analytics: Generate detailed reports and visual dashboards to identify trends and drive improvement.

5. Maintenance Management (CMMS)

Proactive maintenance extends equipment life and minimizes downtime. AIOT MES CONNECT supports advanced maintenance scheduling and predictive capabilities.

- Preventive Maintenance Scheduling: Plan regular maintenance to avert unexpected breakdowns.

- Predictive Maintenance: Leverage data analytics to identify and address potential issues in advance.

- Maintenance Work Order Management: Track and manage work orders for timely and effective maintenance.

6. Data Integration and Connectivity

With AIOT MES CONNECT, ensure seamless data integration across various systems, supporting complete operational transparency and coordination.

- ERP Integration: Synchronize with ERP systems for unified data and coordinated operations.

- IoT Connectivity: Connect with IoT sensors for continuous data capture and process monitoring.

- APIs and Interfaces: Use open APIs for custom integrations, allowing for smooth data flow across applications.

AIOT MES CONNECT is a powerful, user-friendly solution tailored to meet the unique challenges of SMEs, enhancing visibility, control, and decision-making to drive continuous improvement in your manufacturing operations.